Cutting Tool Management

Machine stops due to tool shortages?

Scrap or spindle crashes due to tool loading errors?

Low machine utilization due to short-lifetime tools?

Lot of resources needed for tool renewal work?

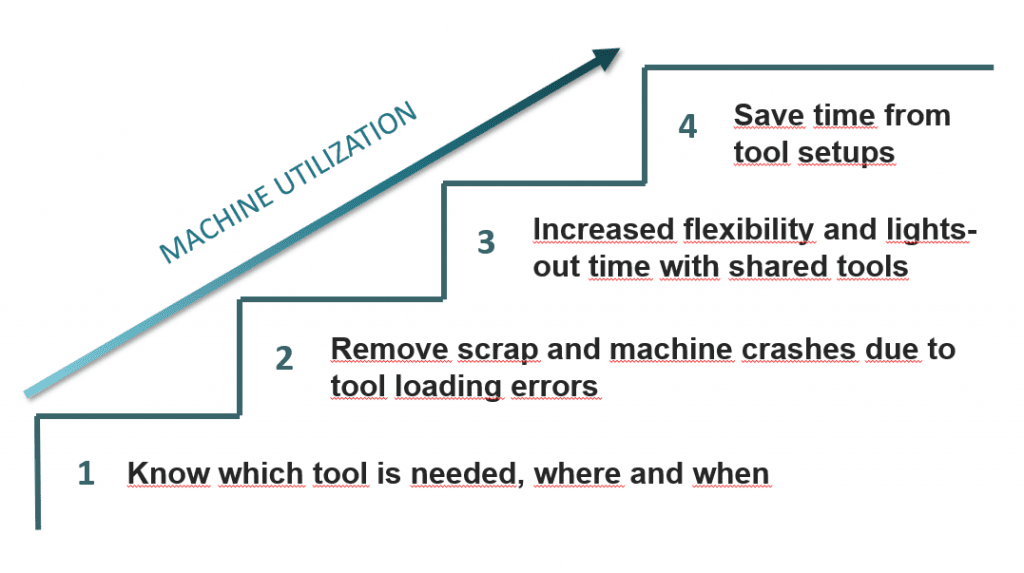

Tool management step by step

With the increasing machining complexity and product variants, cutting tool management has become one of the biggest time thieves on the shop floor. Efficient machine tending processes alone do not help if the cutting tools are what forms the bottleneck – either affecting the shop efficiency, or production quality.

How to start? Fastems typically recommends customers to build their tool management practices step by step, starting from understanding tool needs in advance with the help of Manufacturing Management Software, to highly automated tool sharing and reworking systems.

Cutting tool management allows

Machine tool utilization even above 95%

Zero scrap, zero spindle crashes

Efficient labor usage, improved safety & ergonomics

Fastems tool management offering

Level 1 Tool Resource Monitoring Software

Tool shortages are among the biggest time thieves in production, stopping spindles and requiring action. The first step of tool management is MMS module integrated to the machine tools, telling which tools are needed in which machine and when.

Read more

Level 2 Tool presetter integration

Measuring and enterin 5-digit cutting tool values many times per hour, day by day – in a year it can counts tens or hundreds of thousands manual tool setups. How many errors there are in a year? By using and integrating a tool presetting device, the tool presetting process is greatly streamlined and errors removed.

Read more

Level 3 Centralized Tool Storage

When the materials are challenging, tool lifetimes short or the mix of machines and tools high, centralized tool storage shares the cutting tools between different machines and delivers them automatically into machines based on real-time needs.

Read more

Level 4 Tool Service Cell

If tool lifetimes are extremely short and demand for renewed tools is high, the tool setup process can be automated. With Tool Service Cell (TSC), the only thing operator needs to do is to switch the tool inserts in an ergonomic tool loading station that holds up to four tools at once.

Read more

What do our customers have to say?

Contact us

"*" indicates required fields