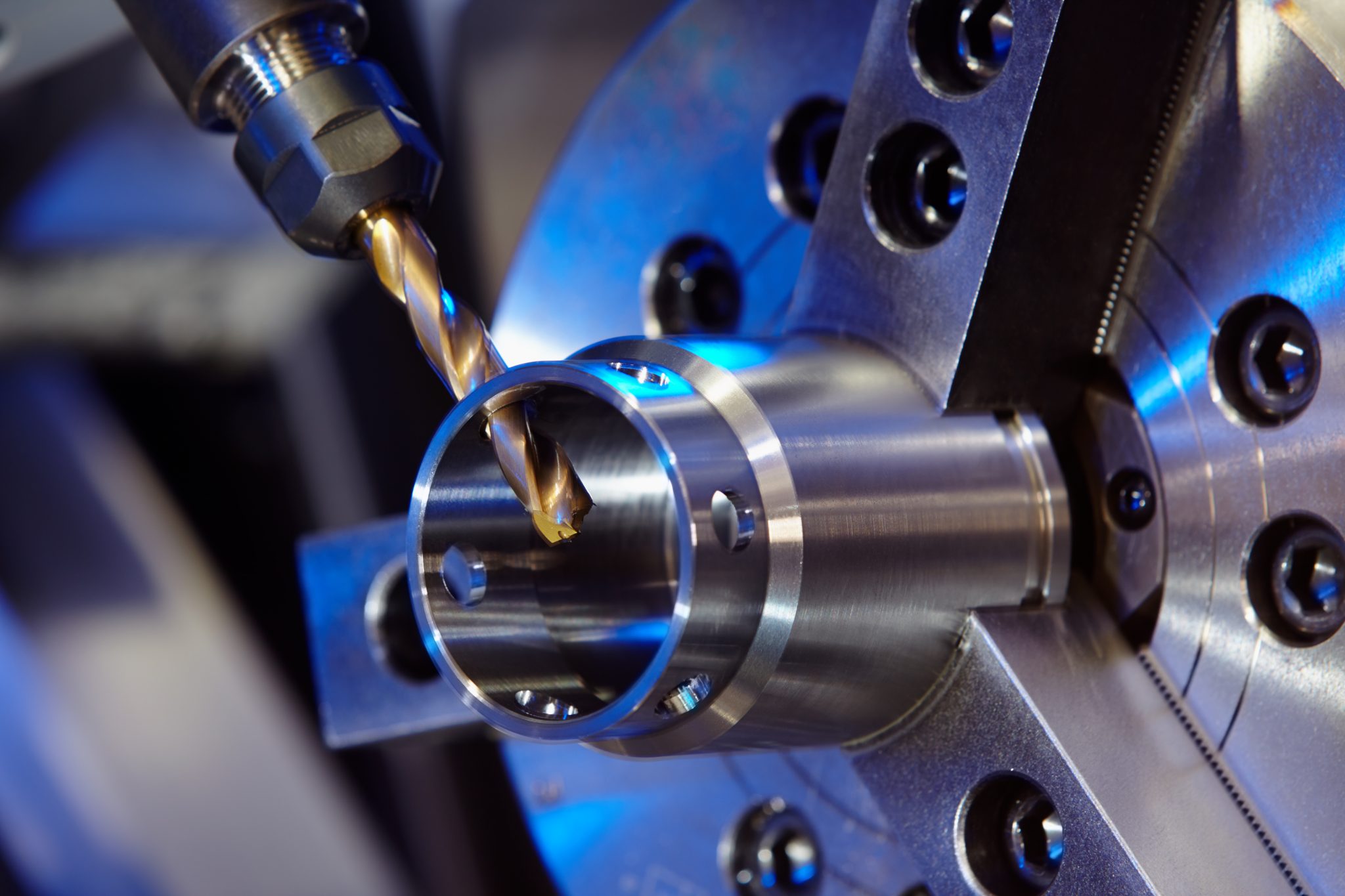

Well-designed fixturing forms the backbone of a successful CNC automation project. The key purpose of a machining fixture is to ensure that the workpieces are securely and accurately held in place during machining. But there are also other criteria for a successful fixturing concept: a good fixture design helps to minimize errors, maximize throughput – and ultimately – enhance the overall quality of the machined components. This blog post lists key considerations when planning to automate your CNC machining centers equipped with pallets or zero-point plates.

What are the Typical Fixtures Used with CNC Automation?

Custom fixturing: When the part mix does not vary too much, or the part shape is extremely challenging, the machine shops can design and manufacture bespoke fixtures for specific parts. The definite upside of this approach is that each fixture can be tailored to fit the needs of each workpiece perfectly and achieve even the highest standards in terms of clamping force or positioning accuracy. The challenge of this fixturing strategy is that designing and manufacturing such fixtures is typically expensive, time-consuming, and requires a high amount of expertise that might not be easily available. If the amount of different manufactured part variants is high, choosing the custom fixturing strategy may lead to an excessive number of varying fixtures and pallets needed in production.

Universal fixturing: Alternative fixture design approach is to use ready-made standard fixture components that can be combined in several ways to form a wide range of fixture assemblies. This means the same fixture components can be used in different fixture applications depending on how each workpiece needs to be clamped. The big upside of this strategy is that the same components are reusable and there is no need to build an individual fixturing for each workpiece from scratch. The typical con is that the standard components provide less room for customizations in case of particularly challenging workpiece geometries.

Combining custom and universal fixturing: It is very typical to combine the best elements from both worlds. Universal fixture components can work as a part of fixture assemblies that have otherwise a custom-made design. Additionally, the choice between manual, hydraulic, and electric power transmission plays a major role in selecting the right fixturing strategy.

A working fixture design helps to clamp parts into pallets quickly and precisely. Together with CNC automation, the right fixturing strategy improves machining efficiency and quality – as well as increases safety and ergonomics of the employees.

What to Consider When Planning Fixturing for Milling CNC Automation?

A well-designed fixture holds the workpiece firmly allowing for repeatable positioning, access to all necessary machining areas, and optimizing machining cycles for automation. From the operation point of view, the loading and unloading times also matter. Those you can minimize with effective fixturing. Here’s how and why fixturing matters especially with CNC automation:

- Precision and accuracy: The machining accuracy is heavily dependent on the stability of the workpiece. Even the slightest movement can lead to out-of-tolerance parts that need to be reworked. When you automate, you want to ensure accuracy because otherwise, you end up with a lot more scrap.

- Repeatability and efficiency: CNC automation ultimately improves efficiency by making manufacturing processes repeatable. Fixtures offer a reliable way of placing the workpiece in the same position for each cycle. Repeatability is essential for keeping tight tolerances across multiple parts and ensuring high manufacturing efficiency.

- Versatility and flexibility: Custom fixtures can be designed for specific parts, but modular fixturing systems offer versatility for various workpieces. Flexible CNC automation can run a wide range of products, and an increasing share of manufacturers are using modular fixtures with it. Whatever your production mix, enabling quick reconfiguration for different jobs is essential – select your fixture types considering that.

- Machining cycle optimization: The transfer capacity of the automation system needs to match the machining cycles and machining rhythm. If the machining operation per workpiece is extremely short and your machine size allows, consider fixturing several components on the same pallet. You can even have multiple different components on the same pallet if the volumes are extremely low.

Fixturing influences the precision, repeatability, and efficiency of automated machining. By investing in effective fixturing solutions and keeping abreast of technological advancements, machining organizations can ensure that their automated CNC operations run smoothly, produce high-quality parts, and are competitive in a demanding industry.

Learn Efficient Fixturing Practices in IMTS 2024!

Going to IMTS in Chicago on September 9-14? Join our partner presentations on Monday, Tuesday and Friday to learn the best designs, options and practices from fixturing specialists!

SEPTEMBER 9, 2024 AT 12:30

Schunk: “Ultimate Flexibility for Fastems FPT System with SCHUNK VERO-S”

Making processes more efficient and making people’s lives easier

SEPTEMBER 10, 2024 AT 12:30

Jergens: “Fixture Optimization for your Fastems system”

How to fixture for “high mix, low volume” part manufacturing and do’s and don’ts of manufacturing parts in a palletized system

SEPTEMBER 13, 2024 AT 12:30

Advanced Machine & Engineering: “Increasing your RPM (Revenue Per Minute) with Advanced Workholding and Automation”

Be Efficient – Be Effective – Be Advanced