Welcome to the CNC Automation Hub of IMTS

Welcome to Fastems ‘Succeed in CNC Automation´ showcase at IMTS booth 338966 in the South Hall in Chicago from September 9-14. Tailored for high-mix manufacturers, Fastems supports machine shops to win the crucial battles of unit cost, lead times and quality. The showcase includes daily education sessions on machine shop productivity and live CNC automation system demonstrations.

SEE LIVE SYSTEMS & SOFTWARE

The Showcases

MILLING AUTOMATION

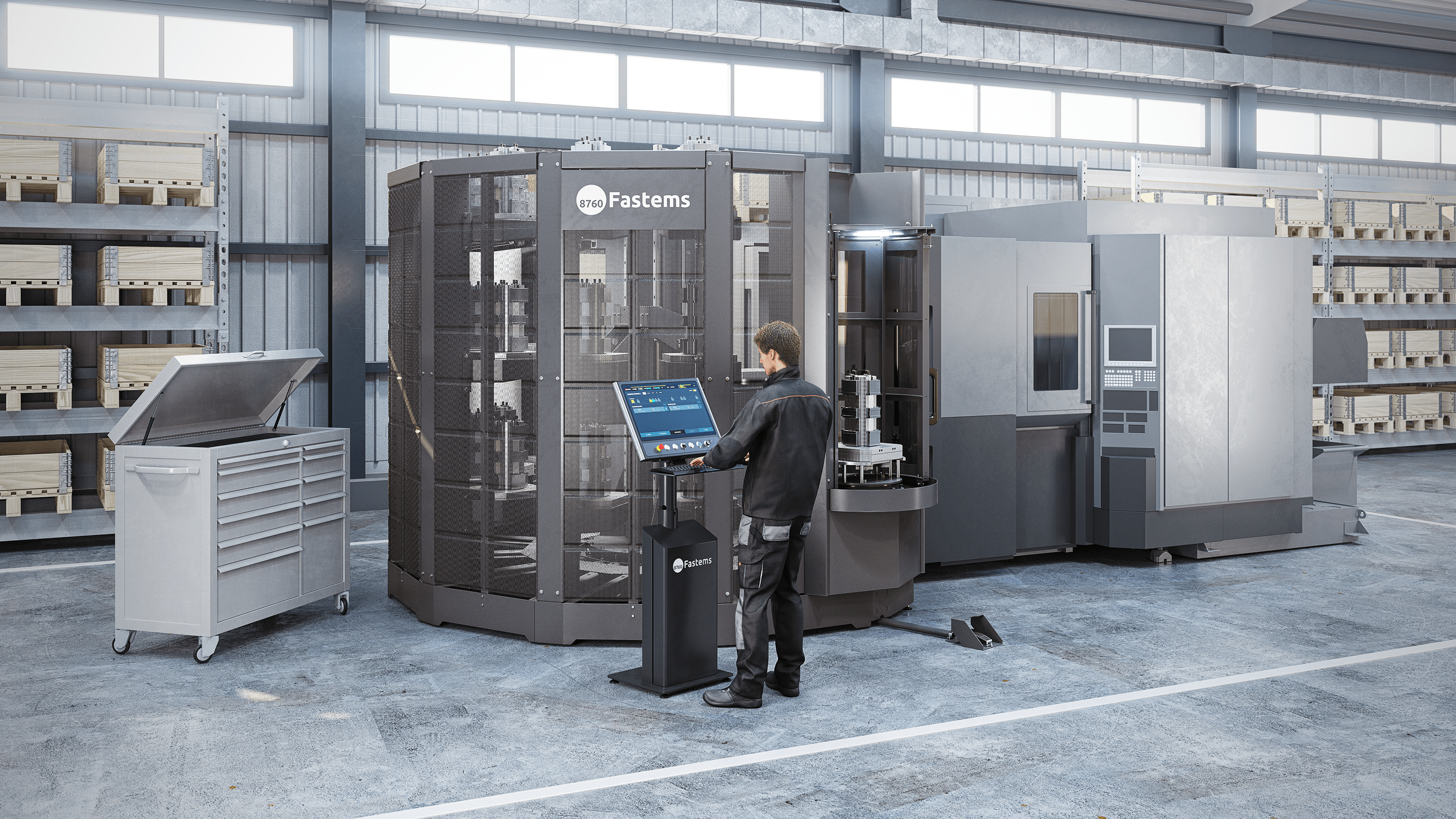

Flexible Pallet Tower FPT

FPT is an affordable and compact automation for your single 4 or 5-axis machine tool configurable 2 to 4-level storage for up to 24 300 to 600 mm pallets. It has a ready-made library of machine interfaces allowing plug-and-play installation for over 90 machine tool brands. This system allows you to increase lights-out capacity, increase machine utilization and shorten lead times.

AUTOMATION SOFTWARE

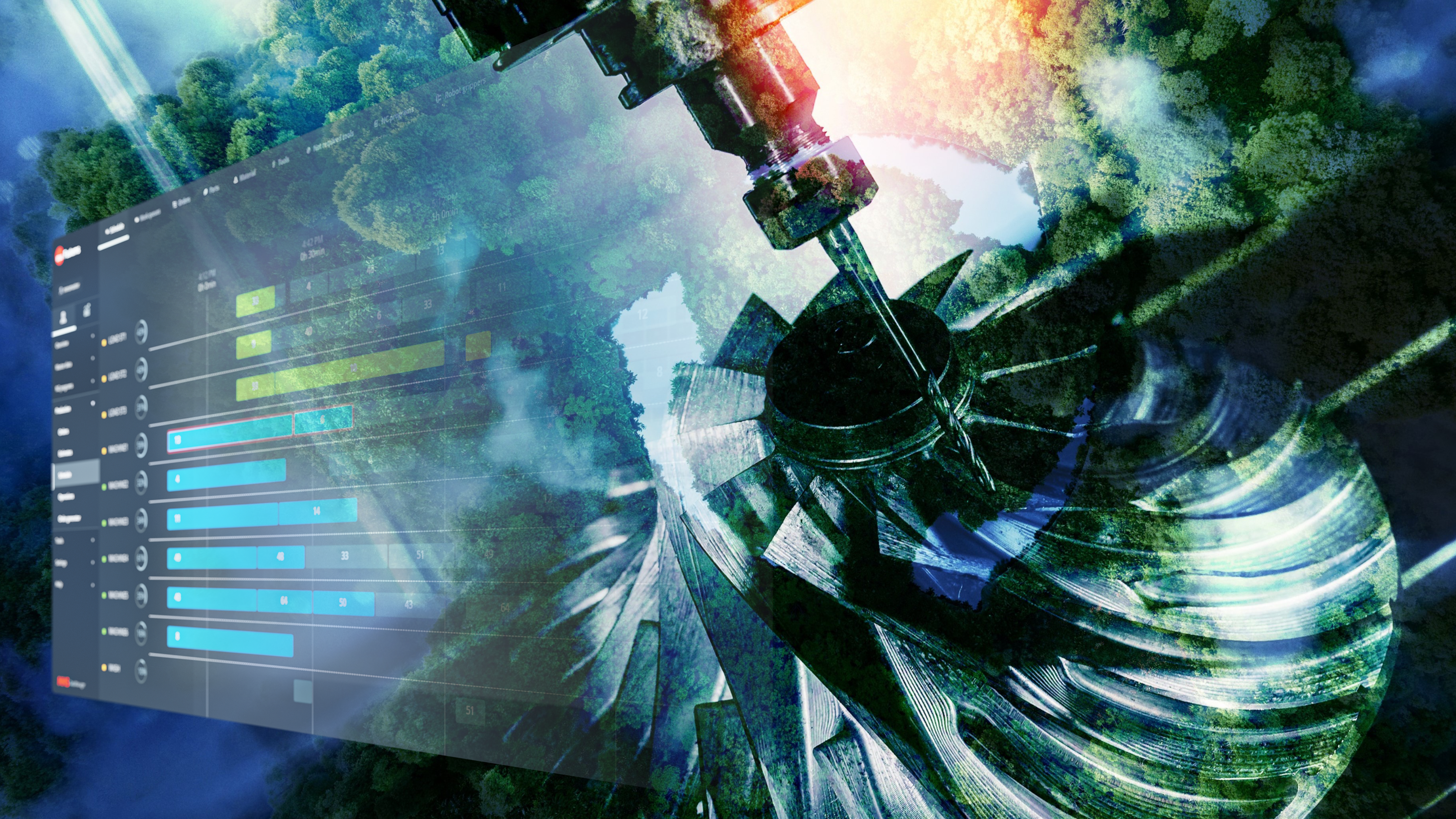

MMS Version 8.2

Manufacturing Management Software, the control of Fastems automation systems, is designed and developed to plan, run and monitor high-mix-low-volume production. Get to know its newest version 8.2 that bring a variety of new features related to machining sustainability, flexible manufacturing for turning CNCs, and much more.

FULL AUTOMATION OFFERING

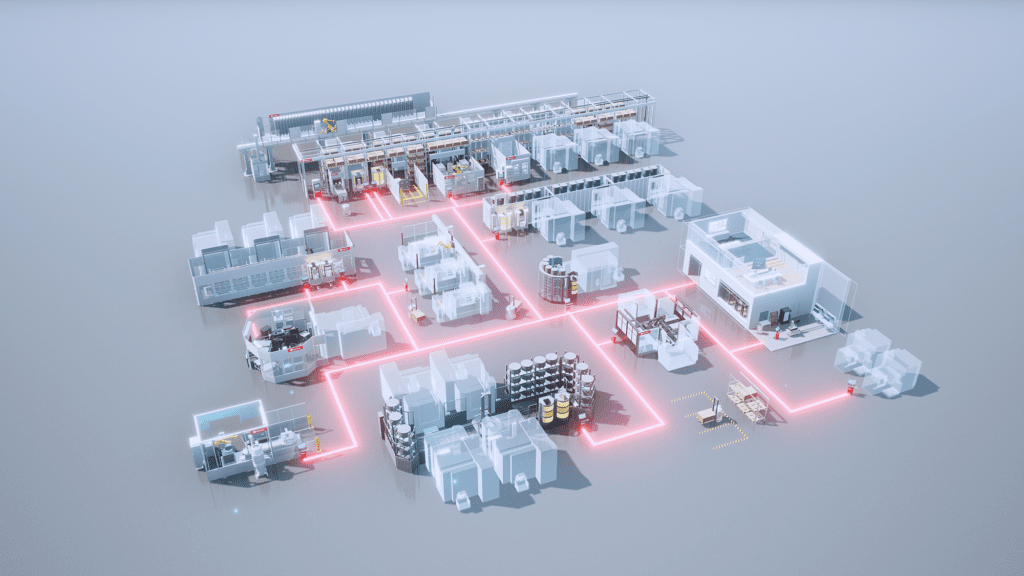

Living Factory

Experience the Fastems automation systems, software and life-cycle services with the interactive platform Living Factory. From single-machine CNC automation to highly integrated systems managing everything from raw materials to a finished and measured parts, you will learn the automation possibilities for over 100 machine tool brands.

DIGITAL MANUFACTURING

Work Cell Operations

Integrate stand-alone machines and manual operations into your existing automation system with Work Cell Operations (WCO) software. Enjoy paperless production, reduced order-to-production time, and transparent data at your fingertips.

DIGITAL SERVICE FOR AUTOMATION

myFastems

myFastems provides digital tools that support and service for all Fastems systems (with MMS6+), enabling real-time, 24/7 information on devices’ activities and statuses for its users. With myFastems, customers are guaranteed of the support throughout the whole lifecycle of their Fastems systems.

DIGITAL MANUFACTURING

Factory Cockpit

Factory Cockpit is the leading cloud service for data-driven manufacturing, helping to solve daily challenges of metalworking manufacturers. The software provides situational awareness by visualizing and analyzing data from production machines and orders in your factory or across factories.

JOIN LEARNING SESSIONS

CNC Automation Theme Days

Join Fastems CNC Automation Theme Days and educational sessions to learn how to optimize your manufacturing operations to reduce setup times and unit cost, enable lights-out manufacturing and handle high part variance efficiently! Here’s the booth program:

| DAY | PROGRAM |

|---|---|

| September 9: Monday | Lunch & Learn SCHUNK at 12:30 PM “Ultimate Flexibility for Fastems FPT System with SCHUNK VERO-S” LEARN MORE |

| September 10: How-To Tuesday | How to automate milling and turning CNCs for flexible manufacturing? 15-minute demonstrations at 11 AM | 4 PM SEE DAY PROGRAM IMTS Conference with Risto Niemi at 10:00 AM “Automation for Everyone! Flexible Automation Systems Open the Door for Shops of All Sizes to Integrate Automatized Solutions Tailored to Their Needs Without Breaking the Bank” READ MORE Lunch & Learn Jergens at 12:30 PM “Fixture Optimization for Your Fastems System” LEARN MORE |

| September 11: Wednesday | Digital solutions for your daily manufacturing challenges on the shop floor 15-minute demonstrations at 11 AM | 4 PM SEE DAY PROGRAM Lunch & Learn Hirsh Precision at 12:30 PM “Promises and Perils of Automated, Flexible Manufacturing in a High-Mix Environment” LEARN MORE |

| September 12: Tool Management Thursday | The best cutting tool practices & tool automation 15-minute demonstrations at 11 AM | 4 PM SEE DAY PROGRAM Lunch & Learn Zoller at 12:30 PM “Lights-out Machining with 100% Process Security” LEARN MORE |

| September 13: Friday | Lunch & Learn Advanced Machine & Engineering at 12:30 PM “Increasing your RPM (Revenue Per Minute) with Advanced Workholding and Automation” LEARN MORE |

Book a Meeting with Fastems Automation Specialist

To reserve a meeting in IMTS with Fastems automation specialist, just select a suitable time from the below Calendly calendar, or drop an email to service.marketing(at)fastems.com.

Talk with Your Local Fastems Team

Give us a call or send an email.

Contact us

"*" indicates required fields