Paperless Production for Non-Automated Operations

Production transparency for non-automated operations with the comprehensive planning & execution software

Extend The Capacity of Your Flexible Manufacturing Systems

In the modern manufacturing, effective production processes no longer only require physical extensions and development, but also benefit from cloud and digitization. Manufacturers are under constant pressure to streamline their operations, maximize resource utilization, and respond swiftly to changing market demands. Understanding the demand, Fastems has developed Work Cell Operations (WCO), a Manufacturing Execution System (MES) software solution designed to empower businesses with the tools they need to revolutionize production planning and scheduling, allowing for flexible connection and integration options that enable managing stand-alone cells. WCO can work either together with your Fastems automation systems, as part of the Manufacturing Management Software (MMS), or as an independent cloud solution, streamlining your whole production process under one control!

This page will go through the following points:

WCO explained in less than 150 seconds

If you find yourself wondering how to plan and manage your production in a productive and efficient way, how big of a WIP do you have, or when is the next free slot to be sold, check out how this advanced software can take your production to the next level, and maximize your profitability. With WCO, you will be able to take control of the manufacturing process of your standalone work cells, from order to production.

The challenges solved by WCO

With more than 40 years of automation experience, we know exactly what the bottlenecks are common in production, even for more advanced factories with established automation systems. WCO is designed and developed together with our customers to attend to the following challenges:

Lots of Excels & Papers

Lack of Production Awareness

Inefficient Material Flow Management

Communications Problems between Shifts

Ineffective Planning & Scheduling

Managers

WCO allows the management personnel to effectively orchestrate production planning, accurately estimate on-time order delivery capacity, and forecast order deliveries well into the future. In addition, managers can monitor their production and track production KPIs more clearly, from which they can easily make data-driven decisions.

Operators

WCO helps operators identify high-priority tasks and have a clear understanding on what needs to be done next, streamlining their daily workload. Addittionally, WCO ensures efficient resource allocation, allowing operators to easily access materials and tools needed for their work.

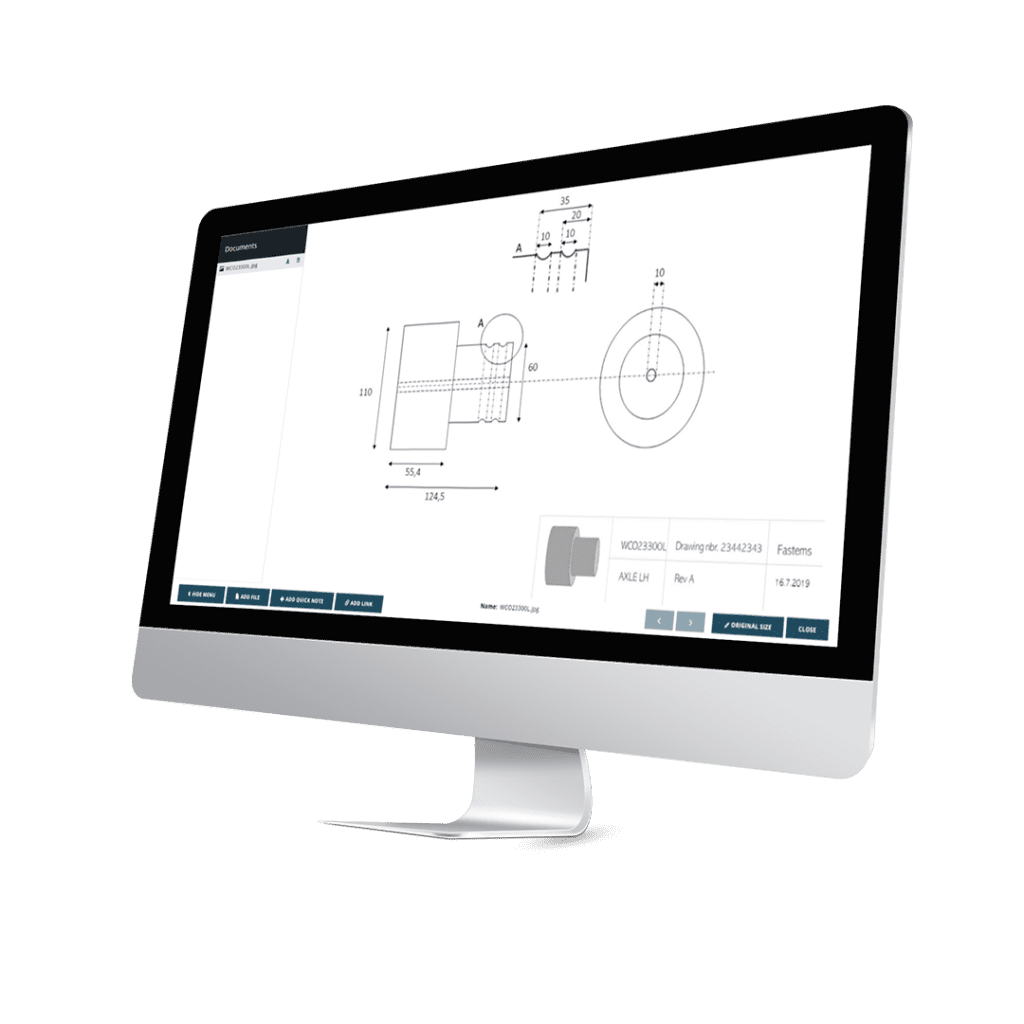

Paperless Production

- Reduce paperwork and digitalize all processes

- All production documents attached to part master data & production, allowing operators to access up-to-date documents whenever needed

Enhanced Production Planning & Scheduling

- Real-time production optimization

- Clear view of upcoming production plan with time estimations

- Highlighted resource deficits

Intelligent Resource Management

- Be informed about the needed and missing resources

- Information for work setup, raw materials. cutting tool and NC programs

Material Logistics Management

- Automatic transfer task lists

- Clear tasks for both internal and external logistics

- Optimized inventory level & minimized carrying costs

Order to Production in No Time

- Easy-to-use order management

- Quick time to value: fast and flexible order input

- Clear views for the end operators of the upcoming tasks

WCO Cloud Edition

- MES Solution hosted at Azure Cloud (see technical specifications here)

- No machine interface required

- Free trial period

- Subscription licensing based on the number of machines or manual operations (work units) after trial period

- No custimization or customer specific feature development, offered as a standard service

WCO On Premise

- MES solution hosted on-premise

- Possibility to be integrated to an existing/new automation solutions

- Higher level machine functionalities available, requiring machine interface connectivity

- Free trial period

- Subscription licensing based on the number of machines or manual operations (work units) after trial

- One-time payment fee for machine interface set up

- Customization or customer-specific feature developments are possible

Identify bottlenecks

Before taking any solution into use, it is important that you know where your issues lie. Do you have papers all around that you cannot keep track of properly? Is it difficult to track order progress, and WIP inventory at each stage for your stand alone machine? Are these creating unnecessary hassles for production management? Finding answers to these problems will help create a foundation for choosing the right solution for your needs. And if you’re not sure, we are always ready to help you find out and give you suitable recommendations.

Consultation Meeting

To validate the needs for your production, we will hold a demo meeting during which our professional maps your production’s needs and challenges, and see how WCO could be utilized for your own production. At this stage, we would bring people and machines into the working loop: defining the user groups

and identifying success criteria. This meeting is about us getting to understand more deeply your factory floor equipment and resources, and about you understanding ways of using the software, so that you can make the most out of your investment!

Implementation & Training

After we have come to agreement on how WCO will be used for your production, the implementation process starts. Thanks to our 40+ years of expertise from the field of factory automation, we have the ability to carry these onboarding processes out with minimum production disturbances – it usually takes no more than a day to get things rolling and most of the work can be done remotely without having to bother your personnel. Where we do have to ask for your active participation, though, is the training part: the customized training delivered by our expert is to ensure that everyone knows how take the most out of your very own WCO for your production needs.

User Testing

During this trial period, you get to put your hands in the mud yourself to see how the benefits of the WCO can be put into practice on your shopfloor. Even though this period is mainly carried out by yourself, we are not going anywhere – if any questions, problems or feedback comes up, you are always free to contact your designated professional from our end. We will also conduct a result analysis of this period and benchmark it against the predefined success criteria, so that you understand the effects of WCO on your production execution. Then, the decision is yours!

Book a Meeting with Our Expert

Please fill in the form below and we will get back to you as soon as possible!

"*" indicates required fields

Customer Reference

Milltamo

Milltamo was one of the first machine shops that implemented WCO Cloud Edition for their production. So far, this has proved to be beneficial for this small family-owned company when there was no heavy investment required to get things rolling, the easiness of use and on-boarding process have been bringing positive results since the day one.

Read more

Joensuu CNC

The company acquired a flexible automation system from Fastems in 2018, as well as the Work Cell Operations (WCO) software for the production planning and resource management of the entire machine shop in 2019. WCO has helped Joensuu CNC see production peaks more clearly, manage the overall situation and the related data and analytics in one place, and reduce the amount of papers and Excels around the production area altogether.

Read more