Skip to content

Agile Manufacturing System

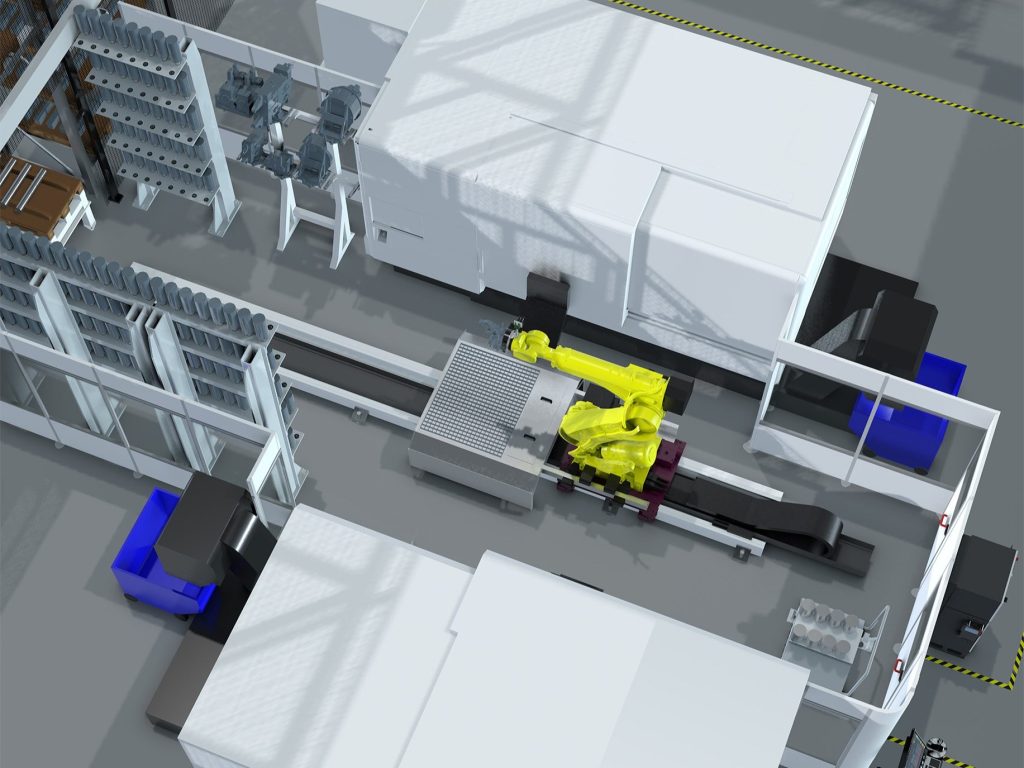

Configuration

- Up to six Mazak 5-axis milling machines supported by an autoloading cell

- Up to six Mazak turn-mill machines supported by robot cell(s).

- Material storage in the middle for raw materials and both milled and turned parts

- AGV tool delivery option

Outcomes

- Unmanned high-mix production in advanced milling and turning applications

- Unmanned new part introduction and re-runs

- Automated set-up changes in milling and turning

- Automated tool delivery and data transfer

- Automated production planning and scheduling

- Just-in-time production

- Situational awareness

- Fast lead times

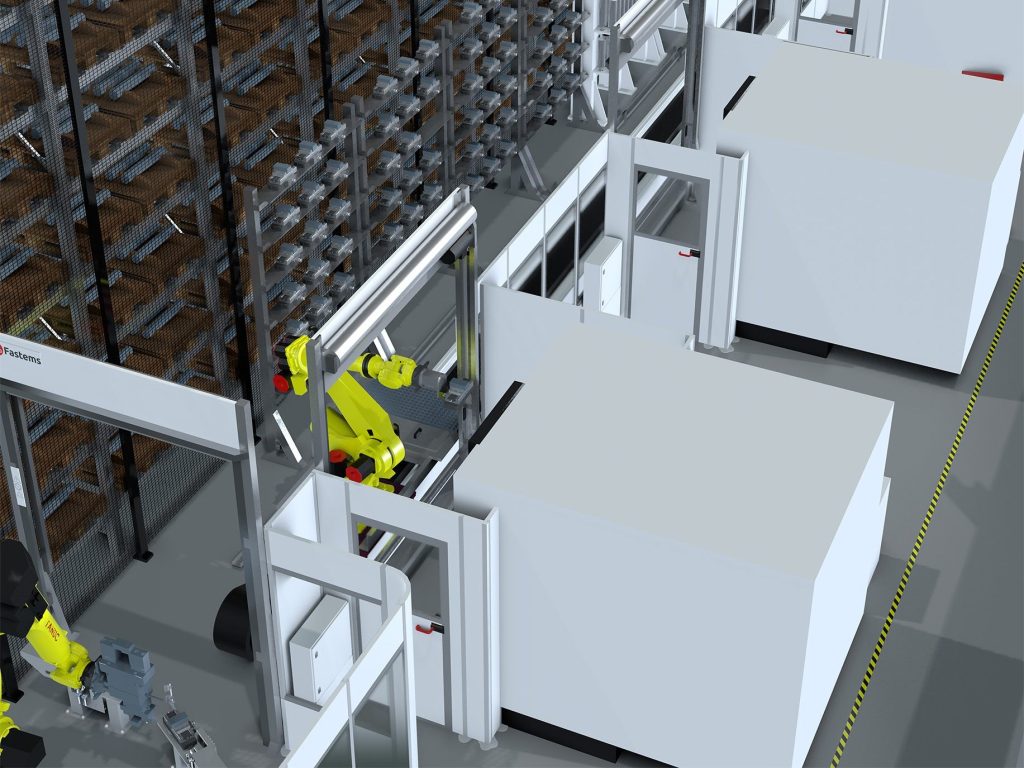

Configuration

- One robot serves two Mazak turn-mill machines.

- Set-up changes happen by changing the chuck.

- Tool change by the robot via magazine door.

- Robot uses different grippers for workpieces, tools and chuck changes

- Chuck jaws can be machined per need when introducing new parts

Outcomes

- Autonomous turn-mill manufacturing

- Automated hard & soft jaw handling

- Automated part handling

- Automated tool & tool data handling

- Automated production planning and scheduling

- Just-in-time production

- Situational awareness

- Fast lead times

Configuration

- Robot serves up to six Mazak 5-axis milling machines

- Zero-point plate delivery to the machine table

- Tool changes via magazine door

- Small buffer for flexibility

- Material input and output via autoloading cell, option for AGV tool management

Outcomes

- Autonomous 5-axis milling manufacturing

- Automated pallet handling

- Minimum (un)loading time, maximum machining time

- Automated tool & tool data handling

- Automated production planning and scheduling

- Just-in-time production

- Situational awareness

- Fast lead times

Configuration

- Material input/output via high-bay storage

- The robot attaches a workpiece to a universal smart fixture and back

- Robot programs are automatically delivered to the robot

Outcomes

- Autonomous part handling

- Automated stock material loading from pallet station into vice

- Automated regripping – from OP10 to OP20

- Automated ready part unloading from vice to pallet station

- Automated production planning and scheduling

- Just-in-time production

- Situational awareness

- Fast lead times