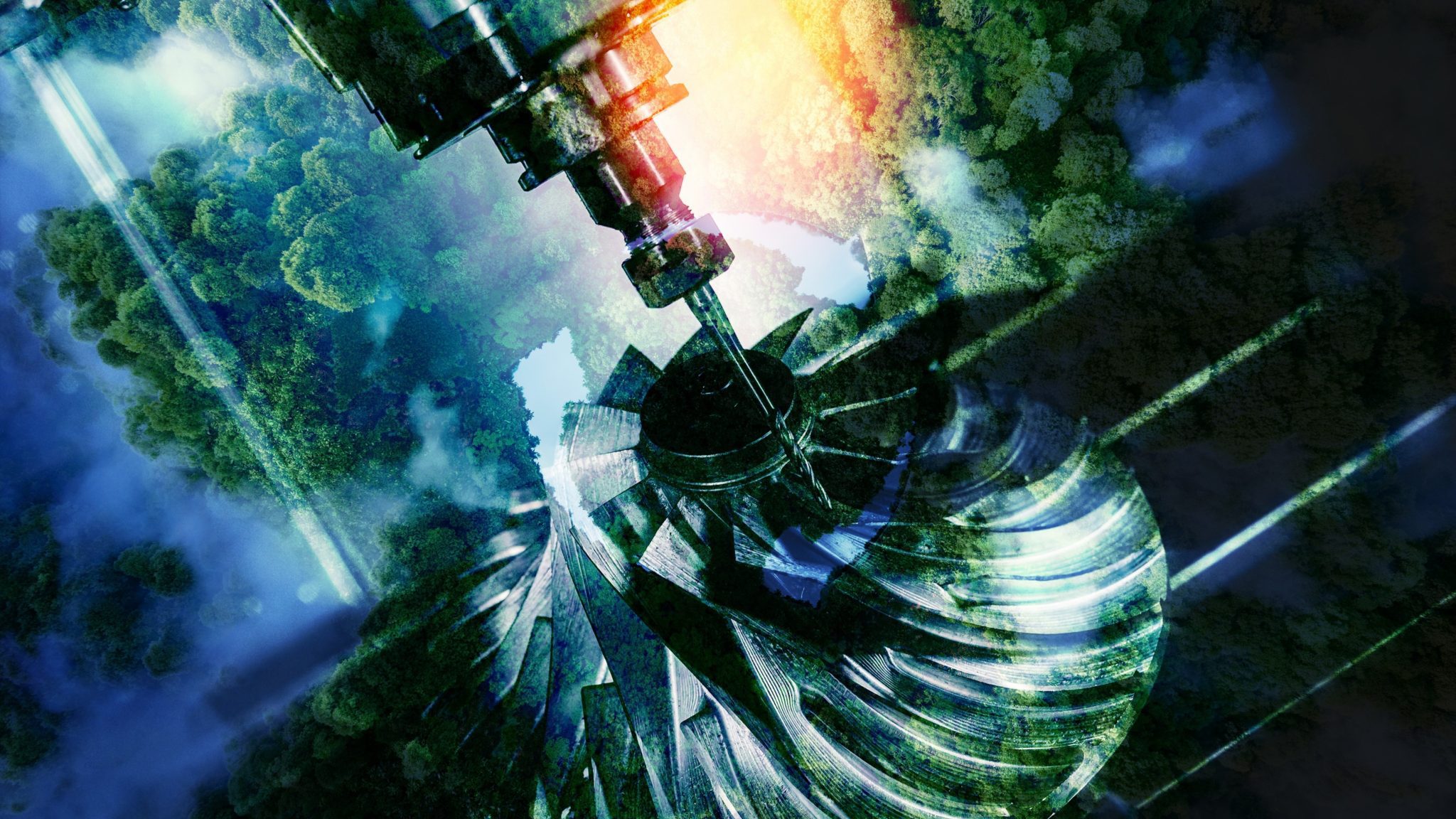

Save costs and inccrease your machining time

Robotic Turret Tool Changer

Flexible Tool Changing for Tool Turrets

Turning part manufacturers with lathes are familiar with lengthy set-up times and high investments in tool holders and tools. Fastems offers a way out of this dilemma with the new automation concept Turret Tool Changer for automated tool changing directly on the turret. Utilizing innovative Sauter SolidPro tool holders, Turret Tool Changer is a robotic tool changing automation for turning machining centers that changes a tool in the tool turret in only a few seconds..

The new concept will premiere at the Fastems booth A43 in hall 10 in AMB Stuttgart, 9-14 September 2024.

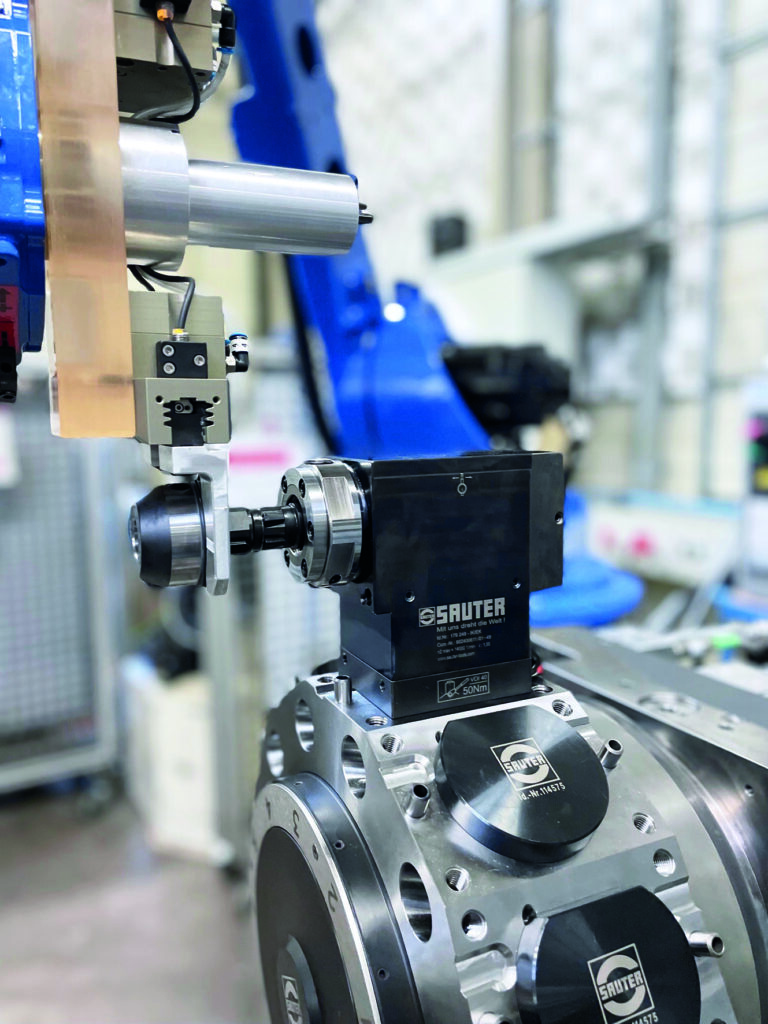

Sauter SolidPro: Modular Quick-Change System

- The new Sauter SolidPro development is an integrable clamping mechanism that turns standard Sauter collet tools into a modular quick-change system.

- Instead of setting up the entire tool inside the machine, each tool can be preset with the Sauter SolidPro adapter outside the machine and then changed easily by turning the actuating bolt.

- This new solution enables clamping a wide variety of adapters easily, fast and with high repeatability.

- The new development also ensures high power transmission from the driven tool during workpiece machining.

- Sauter SolidPro adapter is designed for robotic handling as well – enabling automatic tool changes for lathes.

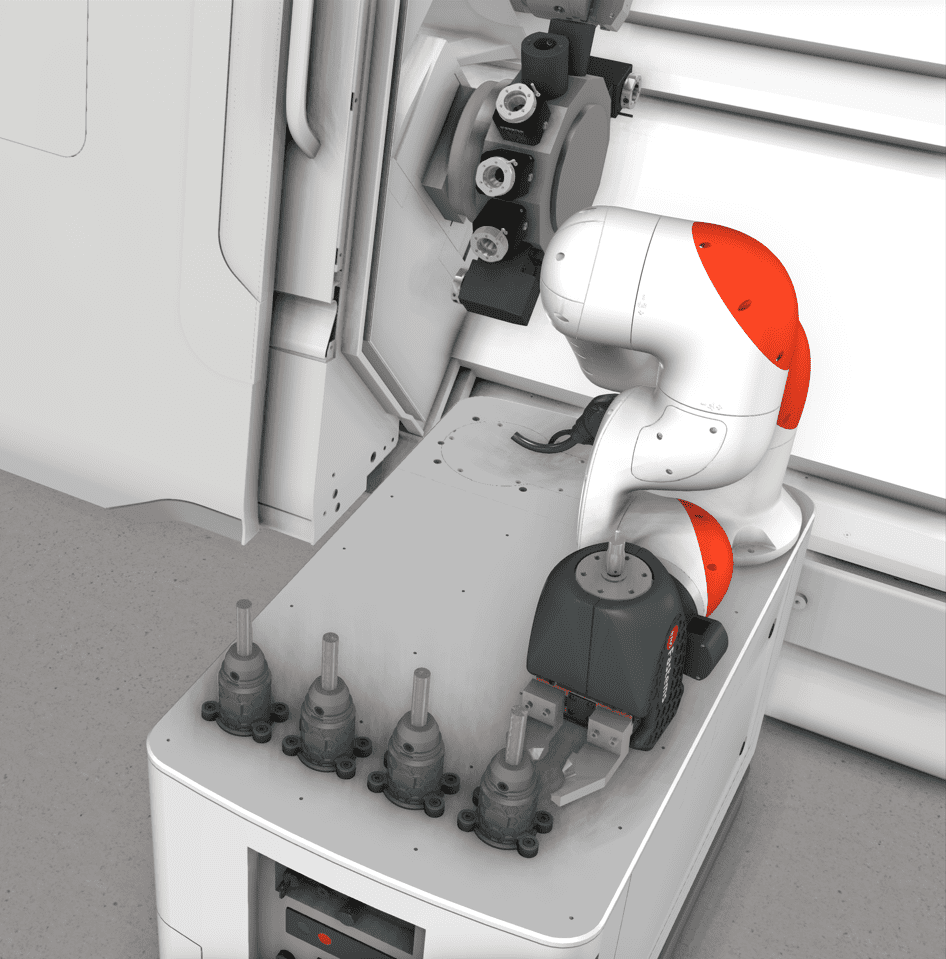

Fastems Turret Tool Changer Concept

- Turret Tool Changer is a robotic tool changing automation for turning machining centers, utilizing Sauter SolidPro technology and changing a tool in the tool turret in only a few seconds.

- The system consists of a robot for tool and workpiece handling, storage locations for Sauter SolidPro adapters.

- The automation control software MMS (Manufacturing Management Software) plans and implements tool changes based on lathe’s machining schedule.

- MMS informs machining operators in advance on which tools to preset and by when.

- Tools can set-up and measured outside the machine with the tool presetter, meanwhile the turning machine is still machining the previous job.

- For automating the cutting tools transfers between tool room and the turning machine, AGVs or AMRs can be integrated into the system as well.

Your Benefits

The Fastems Turret Tool Changer concept with Sauter SolidPro

offers a full range of advantages at various levels:

- Significant savings from tool holders

- Minimized set-up times through automated tool changes

- Extended unmanned machining times

- Higher machine utilization through tool presetting outside the machine

- Support for high-mix production with lower costs for both small and large series, including accelerated chip-to-chip times

Reserve Your Own AMB Demo at a Suitable Time!

To book your own demo session with us in AMB, just can use the below Calendly calendar or email us at service.marketing(at)fastems.com.

Fastems Automation Success Showcase at AMB

In addition to Robotic Turret Tool Changer for multi-tasking lathes, turn-mill machine tools, Fastems is presenting its full offering portfolio including automation for milling and mill-turn machining centers and non-machining processes; various digital manufacturing solutions and productivity-enhancing services. Check our showcases, other theme days and learning sessions at booth A43 in hall 10 here.

Talk with Your Local Fastems Team

Give us a call or send an email.

Contact us

"*" indicates required fields