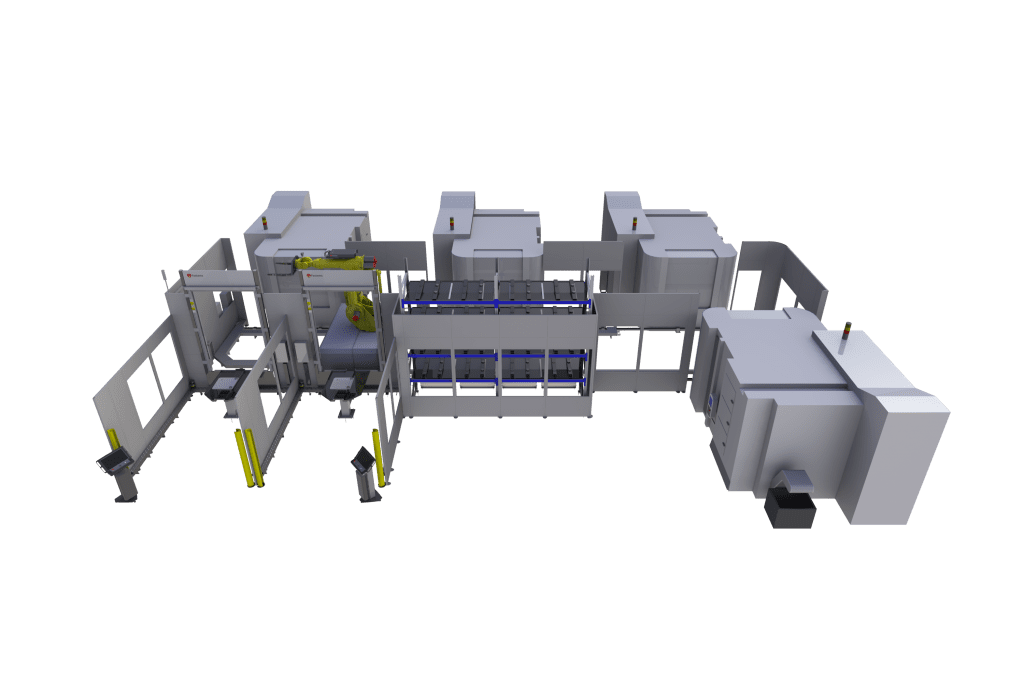

RoboFMS-

Robotic Flexible

Manufacturing System

What is RoboFMS?

RoboFMS does it all

Want to integrate and automate various 5-axis machines with no pallets? Need to include value-adding processes and a large amount of workpieces?

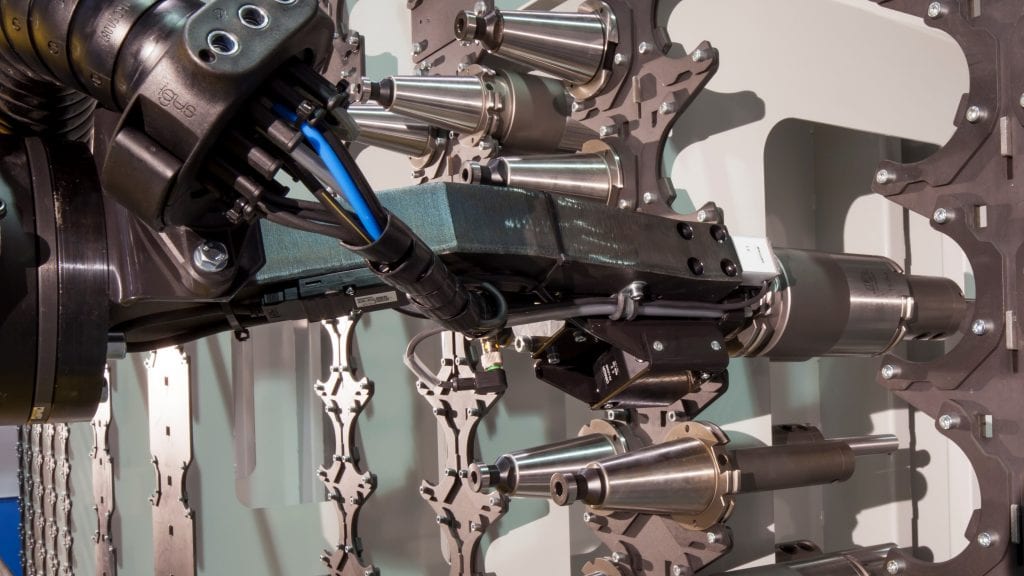

Fastems RoboFMS combines the benefits of an industrial robot and flexible manufacturing system. It brings new flexibility to automating machine tools, with or without automatic pallet changers, and makes integrating part washers, marking machines, measuring devices and other process equipment simple and cost effective.

As every Fastems system, RoboFMS comes with industry’s leading control, MMS, enabling production scheduling and execution.

Why RoboFMS?

Multiple machines, tools and finishing automation in ONE system

Intelligent production planning and scheduling software

Flexible manufacturing for fixed table machining centers

See RoboFMS in Action

What you gain

RoboFMS Benefits:

- High layout flexibility

- Easy extendability

- Ready for additional robotic applications

- Ready for customized integration

- High pallet transfers per hour-capacity

Optimization

Manufacturing Management Software

RoboFMS comes with industry’s finest production planning and execution software, MMS. Manufacturing Management Software is always one step ahead by automatically calculating the optimized production workflow and necessary resources, including tools, based on orders.

MMS adapts automatically to changes in the daily production schedule and displays information to maintain the production output.

Auxiliary processes?

RoboFMS Integrates With

Tool Automation ALD - Autoloading Cells RFC - Robotized Finishing Cells

Need support?

Services for RoboFMS

- 8760 support

- Service agreements

- Maintenance

- Spare parts

- Upgrades

- Relocation

- Training & Consultation

Technical Data

|

System Type |

RoboFMS |

| Nominal Load | 20-2000 kg |

| Maximum Load Size | Custom |

| Pallet Handling Mechanism | Custom |

| Gripping | Schunk NSR, Forks, Custom |

| Travel Length | No limitation |

| Typical Pallet | 300-630 mm ZP plate |

| Storage Height | 2-4levels |

| Setup Stations | LSC-Mini, LSC-LD, LSC-TWIN |

| Coolant Management | Optional |

| Storage Modules | Custom |

| Machine Tool Separation | Automatic roller door + Safety scanner on operator side |

"*" indicates required fields