FPT – Flexible Pallet Tower

What Is FPT?

Plug-and-play Automation for 4 and 5 Axis

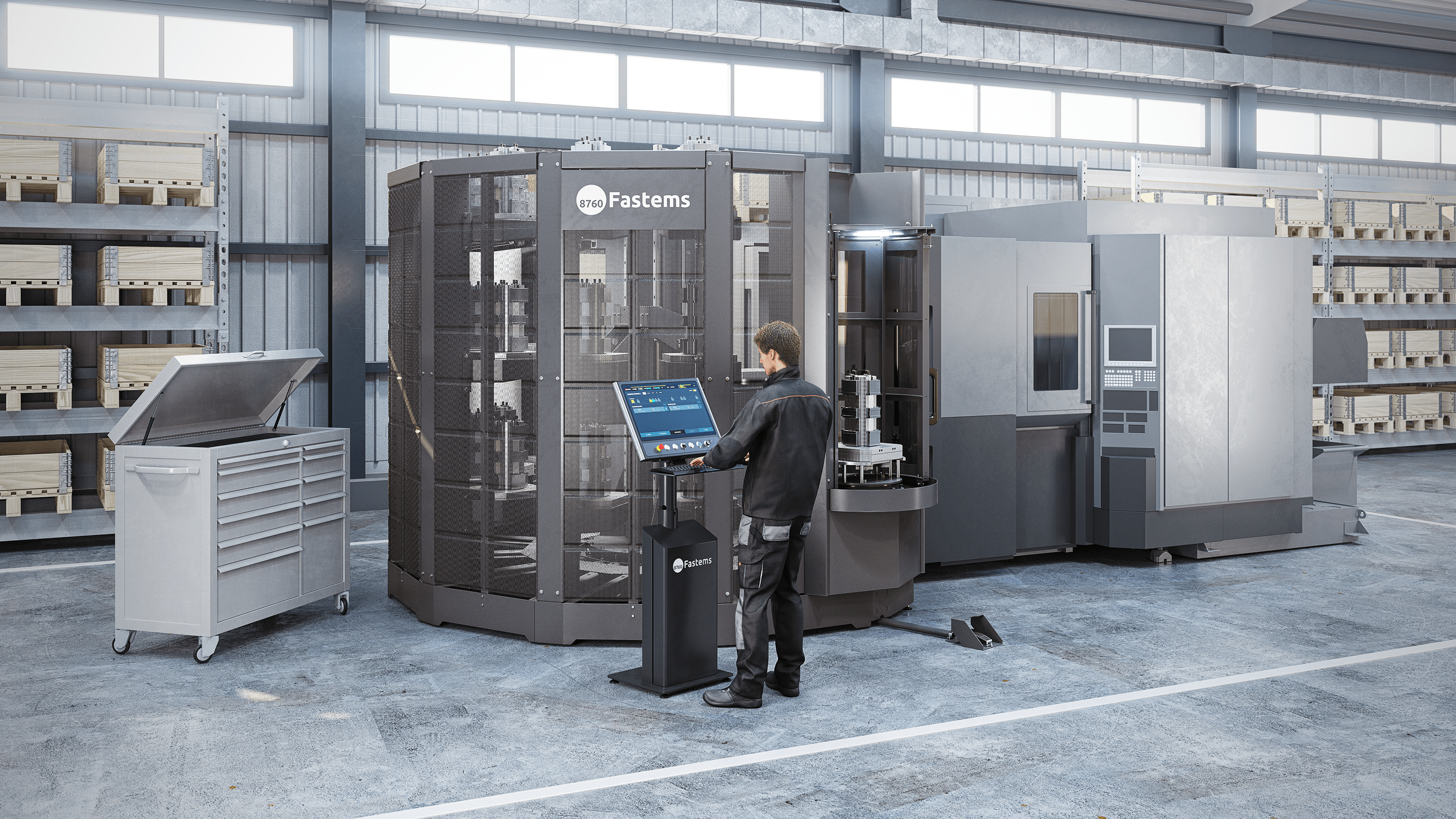

Are you looking for an affordable and compact automation for your 4 or 5 axis machine tool with 300 to 630 mm pallets? With ready-made library of machine interfaces allowing plug-and-play installation for over 90 machine tool brands? Would you like to increase lights-out capacity, increase machine utilization and shorten lead times?

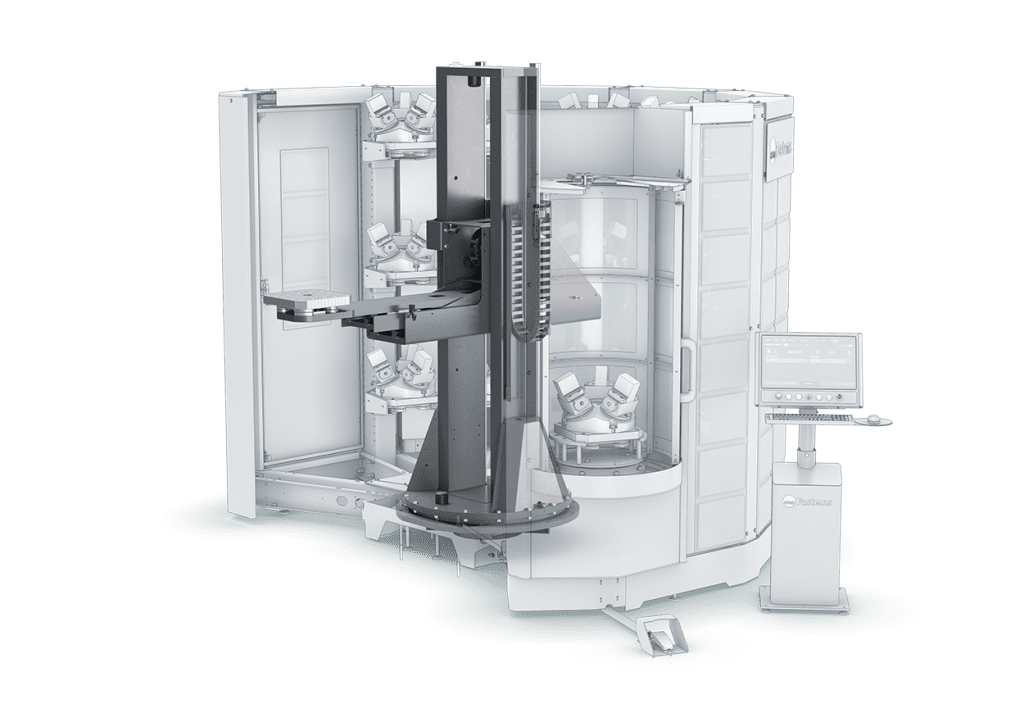

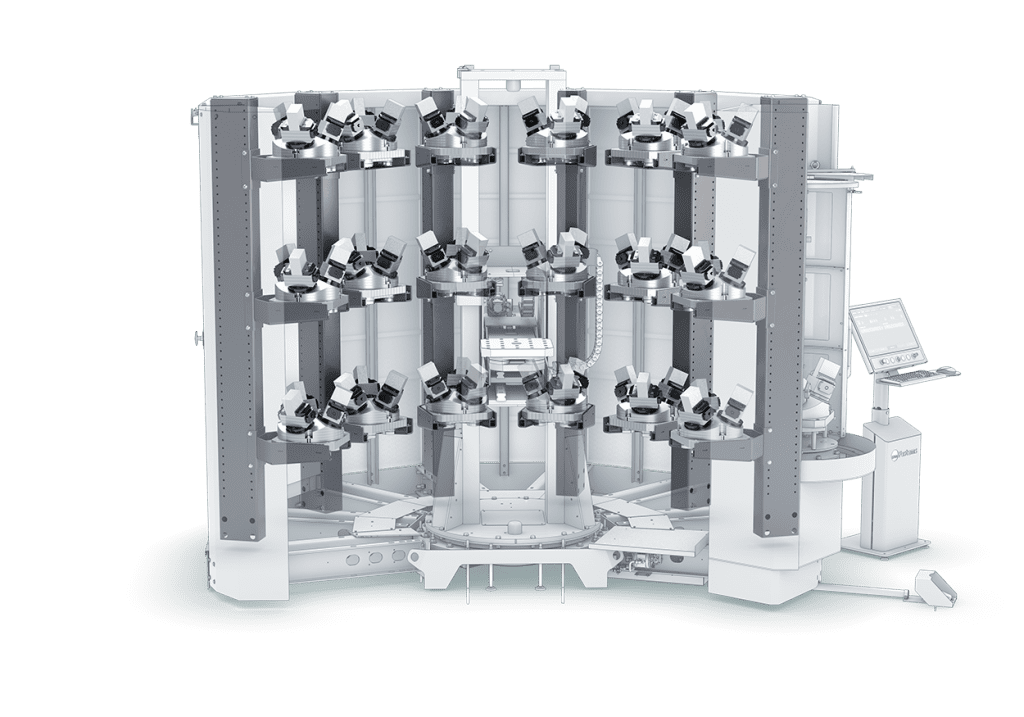

FPT is a compact pallet automation for a single machine tool with or without an automatic pallet changer (APC). FPT features a height configurable 2 to 4 level storage for up to 24 pallets, allowing also for two load heights in one system.

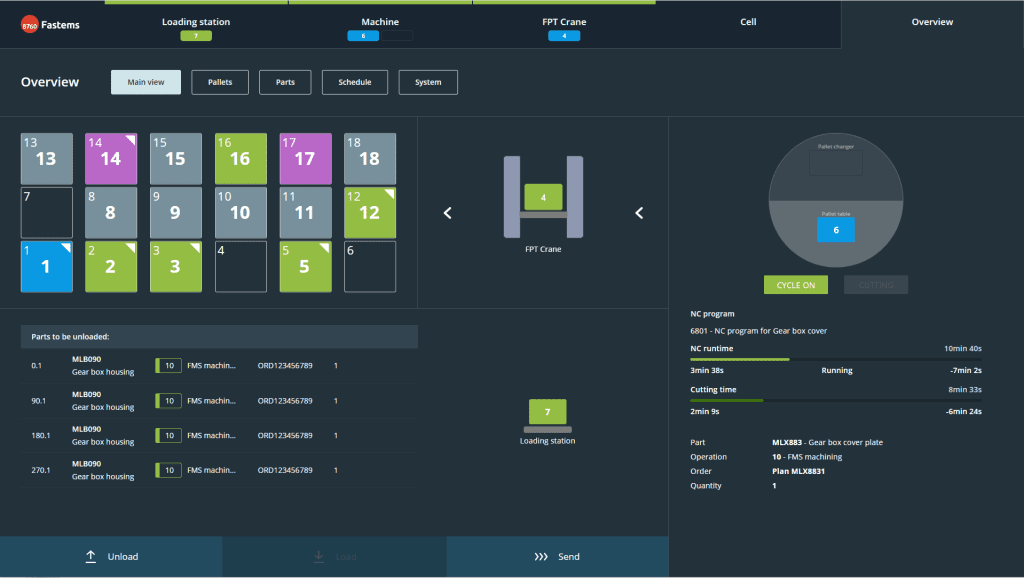

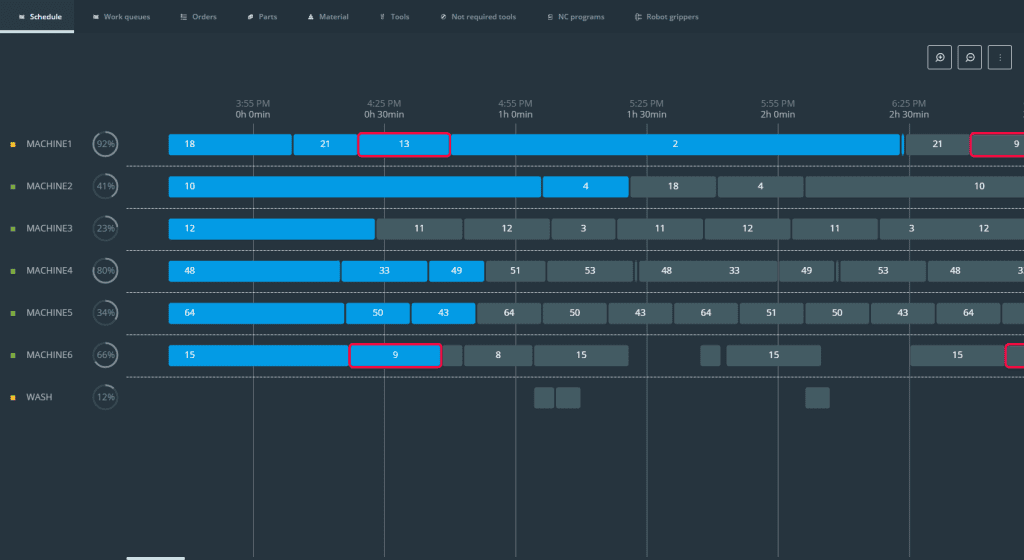

Like every Fastems system, FPT is controlled by Manufacturing Management Software (MMS). MMS offers a single-view user interface with drag-and-drop production order for FIFO, and an order based production scheduling mode with optional ERP integration.

HIGHLIGHTS

Fast-to-deploy automation with reach for hundreds of APC and no-APC machine tools

Compact footprint with configurable storage for up to 24 pallets

User-friendly with ergonomic, rotating loading station and adjustable user panel

COMPARE

The Best Automation for a Single 4 or 5 Axis Machine

| Comparison | No automation | Traditional OEM pallet pool | FPT |

|---|---|---|---|

| Machine tool brand | - | Limited | Any |

| Machine tool type | - | Machines with APC | Machines with/without APC |

| Unmanned production capacity | 1 pallet | Up to 21 pallets | Up to 24 pallets |

| Machine spindle utilization | 40 % | 75 % | 85 % |

| Configurable pallet storage | - | No | From 2 to 4 levels |

| Variable load heights | - | No | Yes |

| Order prioritization | Manual | Queue | Automatic |

| Automatic production planning | No | No | Yes |

| Order priorization | Manual | Manual | Automatic |

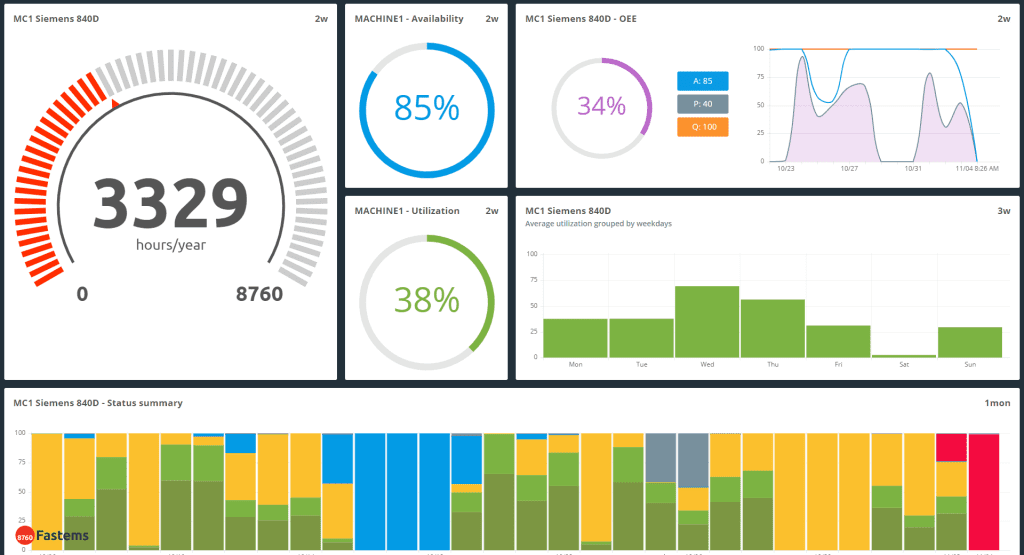

| Automatic real-time KPI reports | No | No | Yes |

EASY USE

Streamline Your Production

MMS, the control software of FPT, is always one step ahead by automatically calculating the optimized production workflow and necessary resources based on your orders. It adapts automatically to changes in your daily production schedule and displays useful insights to maintain the production output.

1 | Easy and Fast to Operate

To make the use as easy as possible, MMS is equipped with a single screen user interface where you can drag and drop your production orders.

2 | Hands-Free Production Planning

In case you want to run truly order-based production, MMS automatic scheduling offers you hands-free production planning that also adapts to changes such as rush jobs automatically.

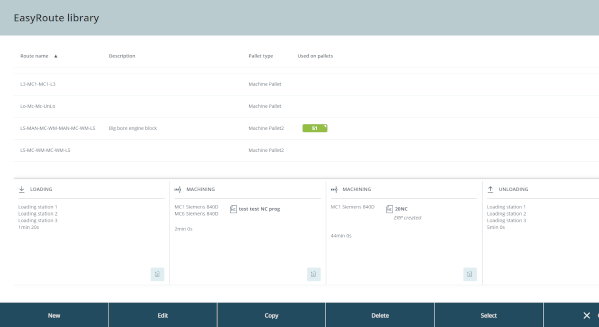

3 | New Workpiece Introduction

Introducing new work pieces into production is possible in under 60 seconds with EasyRoute feature, and MMS Order Generator enables automatic production for recurring or stock balanced orders.

4 | Track Production KPIs

MMS automatically monitors production and reports key performance indicators in real time to the users – as well as gathers production data and gives practical tips on how to improve your productivity even further.

NUMBERS

Technical Data

| Parameter | FPT-500 | FPT-1000 |

| Load weight, incl. pallet | 500 | 1000 |

| Nominal machine pallet size (mm) | 300-500 | 500-630 |

| Load rotational diameter (Ø mm) | 630 | 900 |

| Load height, incl. pallet (H mm) | 1200 (2 storage levels = 12 pallets) 750 (3 storage levels = 18 pallets) 500 (4 storage levels = 24 pallets) | 1200 (2 storage levels = 12 pallets) 900 (3 storage levels = 18 pallets) 600 (4 storage levels = 24 pallets) |

| Length (mm) | 3900 | 5200 |

| Width (mm) | 2900 | 3700 |

| Height, incl. load (mm) | 3000-3500 | 3500-4000 |

| Control software | Fastems MMS | Fastems MMS |

DOWNLOAD

Whitepaper for Automating CNC Milling Machines

This whitepaper discusses topics around shop floor productivity: striving for LEAN manufacturing, what kind of machine tool strategy to select and how to feed the machines with pallet-based automation solutions. We also represent the most typical pallet automation solutions in the market and the production planning methods around them.

"*" indicates required fields

Ready to Find a Solution?

Give us a call or send an email

Contact us

"*" indicates required fields