FPS – Flexible Pallet System

What is FPS?

Modular Automation for 4 and 5 Axis

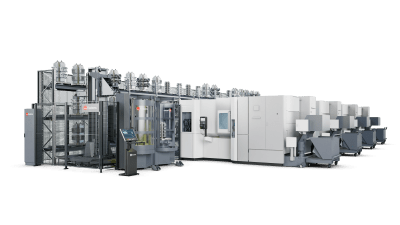

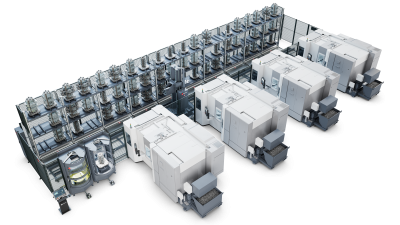

Flexible Pallet System (FPS) enables lights-out manufacturing and high spindle utilization in high-mix production with 4 and 5 axis milling and mill-turn machines, also with compact vertical 5-axis machines. This modular CNC automation solution handles machining pallets and zero-point plates of 300-630 mm and its unique 360-degree design ensures a fit for any shop floor – including tight spaces and low-ceiling facilities. FPS can integrate CNCs of over 90 brands and be extended or upgraded if there is a change in production needs.

The control system of FPS is Fastems’ Manufacturing Management Software (MMS) that is designed specifically for high-mix manufacturing needs. It is a tool for everyone working in production or managing it, giving a real-time view of production activities and identifying exactly what needs to be done next to ensure timely deliveries.

Automate Your Horizontal or Vertical Milling Machines

FPS is a modular automation solution for 4 and 5 axis milling machines with 300 to 630 mm pallets or zero-point plates. The high pallet capacity in a small footprint and automated production scheduling allow for high machine tool utilization and excellent lights out production capacity.

Modular automation with reach for hundreds of milling and mill-turn machine tools with or without automatic pallet changer.

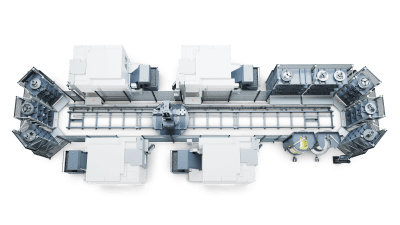

360-degree layout allows placing the CNCs, configurable pallet storage modules and loading stations in any four sides of the system.

The system can be extended later when the production needs change.

COMPARE

The Best Automation for 4 or 5 Axis Machines

The wide integration library with hundreds of machine tools with and without the automatic pallet changer, 360 degree configuration options, and compact yet spacious and configurable pallet storage modules are what make FPS a superior automation solution for milling machines.

| Comparison | Machine with automatic pallet changer | Pallet pool | FPS |

|---|---|---|---|

| Machine tool brands | - | Limited | Any |

| Machine type | - | Machines with APC | Machines with/without APC |

| New or existing machine tools | - | New | Both |

| Unmanned production capacity | 2 pallets | 6-24 pallets | Unlimited |

| Avg machine utilization | 40 % | 65 % | 85 % |

| Machines run per operator | 1 | 1 | As many as the system has |

| Extandability | Buy a new machine | Buy a new system | Plug-and-play extension |

| Automatic production planning | No | No | Yes |

| Order priorization | Manual | Manual | Automatic |

| Automatic real-time KPI reports | No | No | Yes |

EASY USE

Streamline Your Production

MMS, the control software of FPS, is designed specifically for high-mix manufacturing needs. It is a tool for everyone working in production or managing it, giving a real-time view on what happens in production and most importantly, identifying exactly what needs to be done next to ensure timely deliveries and maximum spindle utilization.

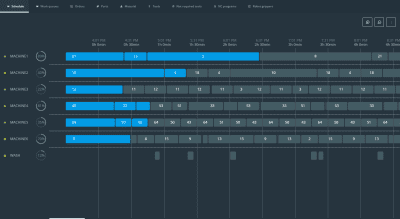

1 | Production Planning

MMS generates production schedule automatically based on customer orders in your ERP or other listing. It also adapts automatically to sudden changes such as rush jobs or machine breaks.

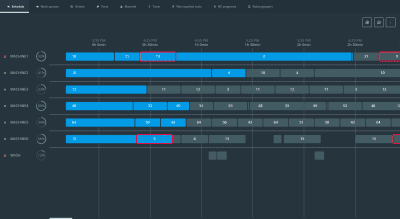

2 | Production Resource Check

All the needed production resources are automatically checked in advance: NC programs, machines, tools, materials and fixtures. MMS guides employees to prepare all the missing resources before the machining is planned to begin.

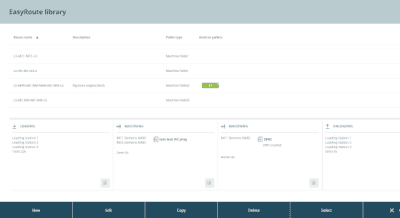

3 | New Workpiece Introduction

Introducing new work pieces into production is possible in under 60 seconds with EasyRoute feature, and MMS Order Generator enables automatic production for recurring or stock balanced orders.

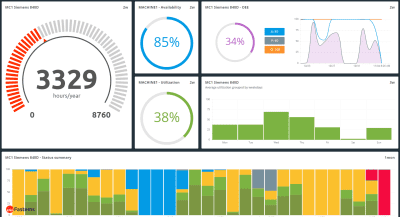

4 | Track Production KPIs

MMS automatically monitors production and reports key performance indicators in real time to the users – as well as gathers production data and gives practical tips on how to improve your productivity even further.

NUMBERS

Technical Data

| Parameter | FPS-500 | FPS-1000 | FPS-1500 |

|---|---|---|---|

| Load weight, incl. pallet | 500 kg (1,102 lbs) | 1000 kg (2,205 lbs) | 1500 kg (3,307 lbs) |

| Nominal machine pallet size | 300-500 mm | 500-630 mm | 500-630 mm |

| Load rotational diameter (Ø) | 630 mm (24.80″) | 900 (35.43″) | 1,100 (43.31″) |

| Load height, incl. pallet(H) | 2 pallets on each level 1200 mm (47.24″) 2 storage levels = 4 pallets 600 mm (23.62″) 3 storage levels = 6 pallets 300 mm (11.81″) 4 storage levels = 8 pallets | 2 pallets on each level 1200 mm (47.24″) 2 storage levels = 4 pallets 800 mm (31.50″) 3 storage levels = 6 pallets 450 mm (17.72″) 4 storage levels = 8 pallets | 2 pallets on each level 1350 mm (53.15″) 2 storage levels = 4 pallets 600 mm (23.62″) 3 storage levels = 6 pallets |

| Side storage modules / base system or 6-meter extension | 4* | 3* | 2* |

| Side storage modules / 3-meter extension | 2 | 1 | 1 |

| Storage places in end storage | 6/9/12 (depending on load height) | 6/9/12 (depending on load height) | 4/6 (depending on load height) |

| Base system length | 7150 mm (281.5″) | 7350 mm (289.37″) | 7750 mm (305.12″) |

| Extension lengths | 2980 mm (117.32″) / 5960 mm (234.65″) | 3040 mm (119.69″) / 6120 mm (240.95″) | 3040 mm (119.69″) / 6120 mm (240.95″) |

| End storage length (mm) | 800 mm (31.50″) | 1200 mm (47.24″) | 1250 mm (49.21″) |

| Width (mm) excl. stations | 3250 mm (127.95″) | 4050 mm (159.45″) | 4300 mm (169.29″) |

| Height, incl. load (mm) | 3100-3650 mm (122.05-143.70″) | 3500-4100 mm (137.80-161.42″) | 3500-4150 mm (137.80-163.39″) |

| Transport height | 2800 mm (110.24″) | 2800 mm (110.24″) | 2800 mm (110.24″) |

| Control software | Fastems MMS | ||

* base module includes 2 side storage modules as default

DOWNLOAD

Guide: Automating Milling Machines

This whitepaper discusses topics around shop floor productivity: striving for LEAN manufacturing, what kind of machine tool strategy to select and how to feed the machines with pallet-based automation solutions. We also represent the most typical pallet automation solutions in the market and the production planning methods around them.

"*" indicates required fields

Contact us

Ready to Find a Solution?

Give us a call or send an email.

"*" indicates required fields