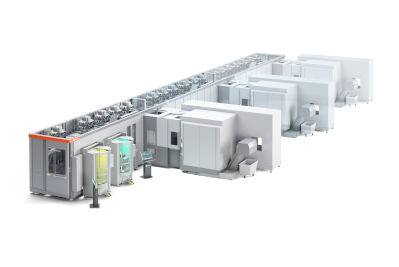

FPC – Flexible Pallet Container

Easy and Extendable Pallet Automation

Are you looking for an easy and factory tested automation solution for 1-3 machine tools? With excellent options for future extensions? Would you like to have good ergonomics and excellent user experiences?

FPC is a standardized pallet automation solution easily superseding pallet pools or automatic pallet changers. It can be extended for up to 3 machine tools and thanks to the state-of-the-art software MMS, is capable of production scheduling and execution, enabling transparent and reliable delivery times. FPC also features lights out manufacturing.

FPC is a factory tested unit ensuring quick on-site operations and production ramp-up.

Automate Your Milling Machine

FPC is a fast-to-deploy and easy to use automation solution for milling machines with 400 to 1000 mm pallets. The high pallet capacity in a small footprint and various production scheduling options allow for high machine tool utilization and excellent lights out production capacity. The system can also be extended for up to 3 machine tools by just simply adding one or two extra containers!

“Our machine utilization raise from 30% to 70% and the setup times halved. Now we can produce small batches and high mix of parts economically.”

CEO of Kytola Instruments

Integrate with any machine tool brand

First you select the right horizontal machining center for your production needs. We can automate nearly any milling machine – FPC has already been integrated with hundreds of different machine tools, and the number is constantly rising.

Fast delivery and ramp-up

It is an easy and factory-tested first-step pallet automation for milling machines. FPC is a plug-and-play solution and its deployment only takes days. FPC increases the spindle hours, cuts setup times close to zero and enables lights-out manufacturing. It also adapts to any changes in your job list automatically.

Extends from 1 to 3 machine tools

The world is constantly changing, and the production needs as well. That’s why we want to provide not only a solution for today, but also an investment that pays back tomorrow. FPC can be later extended to run up to three milling machines, thus covering your future growth as well. Plug-and-play.

The Best Automation for 1 to 3 Milling Machines

The wide integration library, extensibility and various scheduling capabilities with real-time production monitoring are what make FPC a superior automation solution for milling machines.

| Comparison | Machine with automatic pallet changer | Pallet pool | FPC |

|---|---|---|---|

| Unmanned production capacity | 2 pallets | 6 pallets | Up to 12 pallets per machine (max. 36) |

| Avg machine utilization | 40 % | 65 % | 85 % |

| Machines run per operator | 1 | 1 | 3 |

| Cost of automation | None | 100.000 € per machine | 130.000 € + 60.000 € per added machine |

| Extandability | Buy a new machine | Buy a new system | Add a plug-and-play extension |

| Automatic production planning | No | No | Yes |

| Order priorization | Manual | Manual | Automatic |

| Automatic real-time KPI reports | No | No | Yes |

| Floor space (incl. operation space) | 40 m2 (120 m2 for 3 machines) | 60 m2 (180 m2 for 3 machines) | 66 m2 (160 qm2 for 3 machines) |

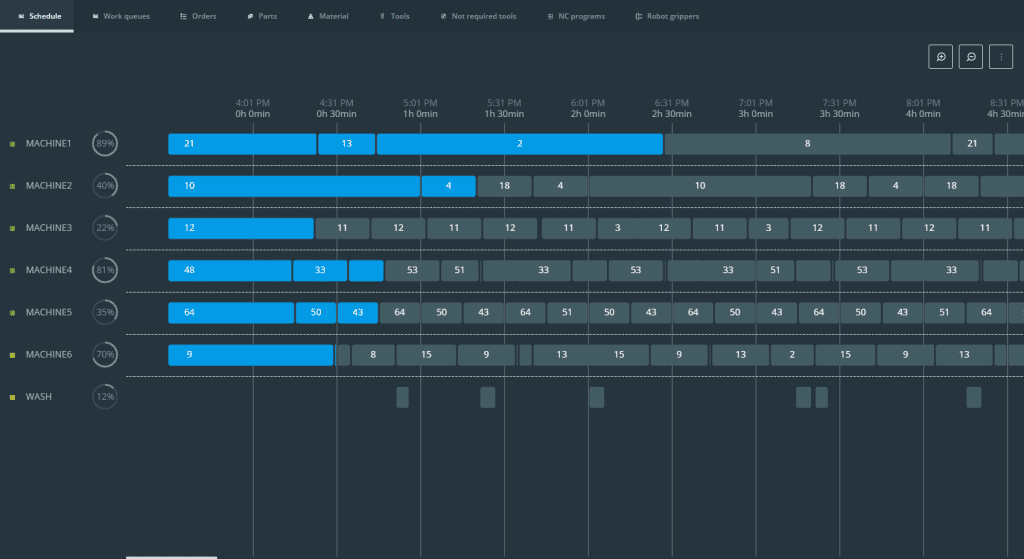

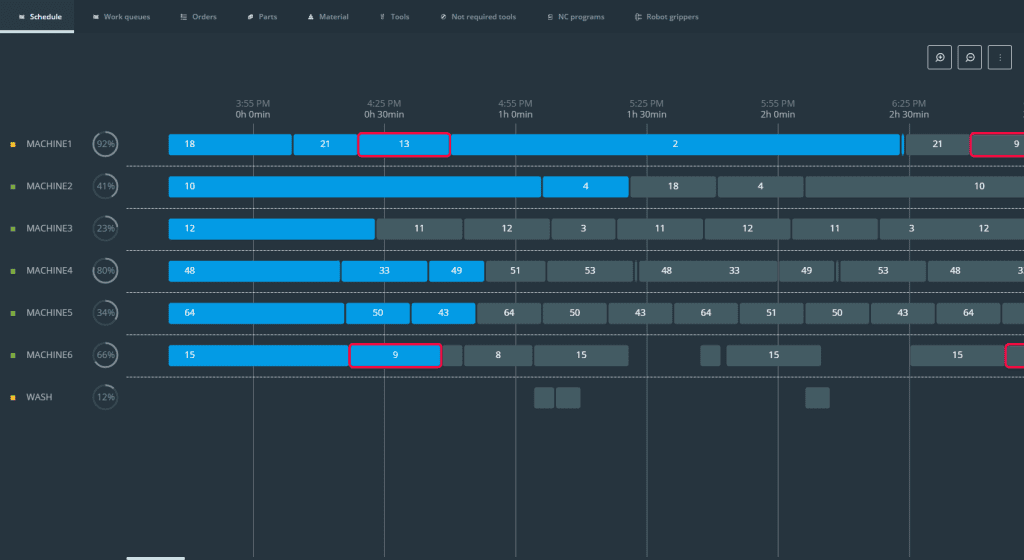

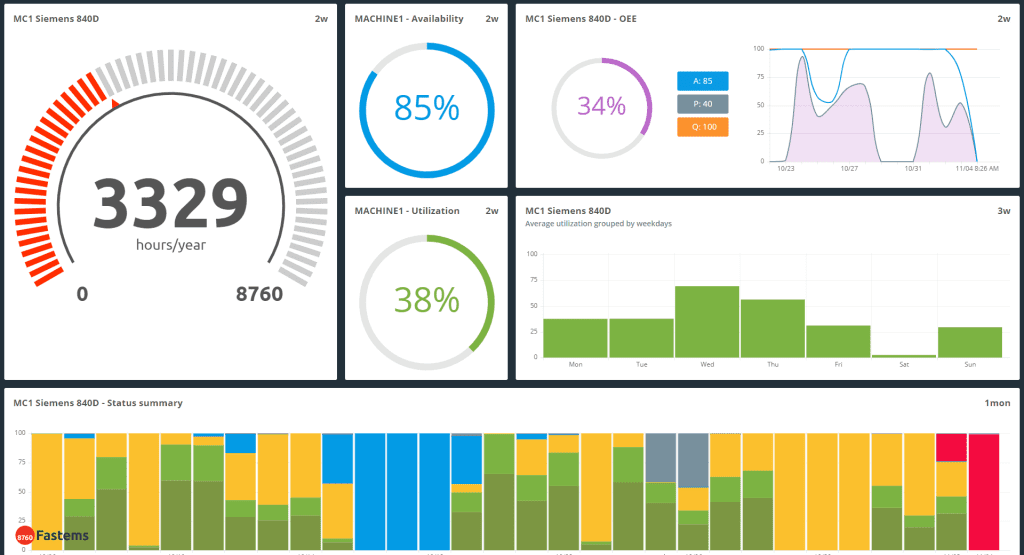

Manufacturing Management Software

MMS, the control software of Fastems automation systems, is designed specifically for high-mix manufacturing needs. It is a tool for everyone working in production or managing it, giving a real-time view on what happens in production and most importantly, identifying exactly what needs to be done next to ensure timely deliveries and maximum spindle utilization.

1 | Production Planning

2 | Production Resource Check

3 | Production Execution

4 | Following Production KPIs

Technical Data

| Parameter | FPC-750 | FPC-750XL | FPC-1000 | FPC-1500 | FPC-1800 | FPC-3000 |

| Load weight, incl. pallet (kg) | 750 | 1000 | 1500 | 1800 | 3000 | |

| Nominal machine pallet size (mm) | 400×400 or 500×500 | 500×500 or 630×630 | 630×630 or 630×800 | 630×630 or 800×800 | 800×800 or 1000×1000 | |

| Load size(X x Z mm) | 750×750 | 950×950 | 1050×1000 | 1050×1000 | Ø1600 | |

| Load rotational diameter(Ø mm) | 800 | 1250 | 1250 | 1250 | 1600 | |

| Load height, incl. pallet(H mm) | 900 | 1100 | 1200 | 1325 | 1800 | |

| Storage capacity by container unit | 12 | 16 | 10 | 10 | 12 | 6 |

| Length, base container (mm) | 7200 | 9235 | 7530 | 9240 | 9240 | 11500 |

| Length, extension container (mm) | 6910 | 8980 | 7270 | 8980 | 8980 | 11500 |

| Width (mm) | 2250 | 2380 | 2380 | 2380 | 3600 | |

| Height, container (mm) | 2800 | 2800 | 2800 | 2880 | 2900 | |

| Maximum height (mm) | 3850 | 4150 | 4150 | 4280 | 2900 | |

| Control software | MMS | |||||

Download Whitepaper for Automating CNC Milling Machines

This whitepaper discusses topics around shop floor productivity: striving for LEAN manufacturing, what kind of machine tool strategy to select and how to feed the machines with pallet-based automation solutions. We also represent the most typical pallet automation solutions in the market and the production planning methods around them.

"*" indicates required fields

Ready to find a solution?

Give us a call or send an email

Contact us

"*" indicates required fields