Process Integration Raises Productivity and Quality

CNC manufacturing is more than machining: the workpieces often require finishing, washing, measuring or marking operations to be ready for shipping. Sometimes assembly, welding or heat treatment operations can be necessary. The process might also include tool pre-setting with a dedicated device or moving workpieces or tools with an AGV system. These processes and devices can be automated by integrating them to be a part of an automation system. This results in more unmanned production capacity, shorter lead times, more stable quality and more.

What CNC Supportive Processes or Devices to Automate?

Below you can see the main categories of supportive devices and processes that Fastems integrates and automates. In reality, the list is longer and if you don’t find your device/process there, be in touch with your local Fastems representative!

Measuring, Marking or Washing

Fastems has plenty of experience in integrating washing, measuring, marking and other processes and machinery. See following example of SKF where measuring, cleaning, finishing and tool pre-setting has been integrated into one system, controlled with our MMS. Measuring process integration also supports the advanced traceability features of MMS.

Below you can see a list of the most typical integrated brands in each category in alphabetical order. There are also other brands as part of our systems and adding a new brand is not a problem.

Measuring (CMM) and visual quality assurance

- Hexacon, Lentz, Mitutoyo, Nikon, Renishaw, Zeiss

Marking (e.g. laser and dot peen marking, engraving)

- Markator, Technomark, Telesis, Trumpf

Washing

- Aquaclean, Teijo

Other devices & processes

- Assembly cells

- Welding cells

- Heat treatment cells

- Cutting fluid management systems (e.g. by Accustrip)

Deburring or Other Finishing Operations

After machining workpieces typically require at least some finishing such as de-burring, grinding or polishing. Fastems has a long history in integration of these operations that can be handled with dedicated machinery or by using our robotic finishing cell RFC. See the above video for some examples.

Cutting Tool Automation

Automating tool transfers to and from machine tools and transferring tool + off-set data to machines tools can be automated using our MMS software. See more information in the cutting tool automation page. Below you can see a list of the most typical integrated brands in each category in alphabetical order. There are also other brands as part of our systems and adding a new brand is not a problem.

Tool Data Management software:

- TDM

- Wintool

- Zoller

Tool Pre-setter devices:

- Haimer

- Mitutoyo

- Speroni

- Zoller

Automatic Guided Vehicles (AGVs)

Fastems has supplied many automation systems utilizing AGVs and we see their usage to increase in the future as their versatility and agility are excellent. You can read more about AGVs here. As part of Fastems’ automation systems, AGVs are usually utilized in three ways:

- Inbound and outbound material logistics for an automation system (supplying raw materials, transferring ready workpieces)

- Transporting workpieces between different process phases within the automation system

- Transporting cutting tools between storage, pre-setter, and machine tools

Our MMS control can be integrated to AGV’s dedicated control so that production planning and scheduling features of MMS get translated to rules for the AGV operations.

Higher revenue and profits with less tied capital

Integrating CNC machining supportive processes and devices into an automation system leads into higher utilization of resources by enabling unmanned production, more throughput and higher quality. In short: the production achieves higher volumes and profits and operates with less money (less stocks and WIP).

Less idling, more capacity, higher quality and easier production planning

Intelligent automation and process integration makes sure planned production will happen – oftentimes without human intervention. This means less waiting (OEE), shorter lead times and stable and high quality.

Happier people, customers and planet

Automation helps fighting the challenges of finding and keeping skilled labor and being able to deliver quality on time. By increasing resource efficiency and making jobs more meaningful, safe and accessible it also supports in reaching sustainability targets.

To better understand automating CNC supportive processes or devices start here:

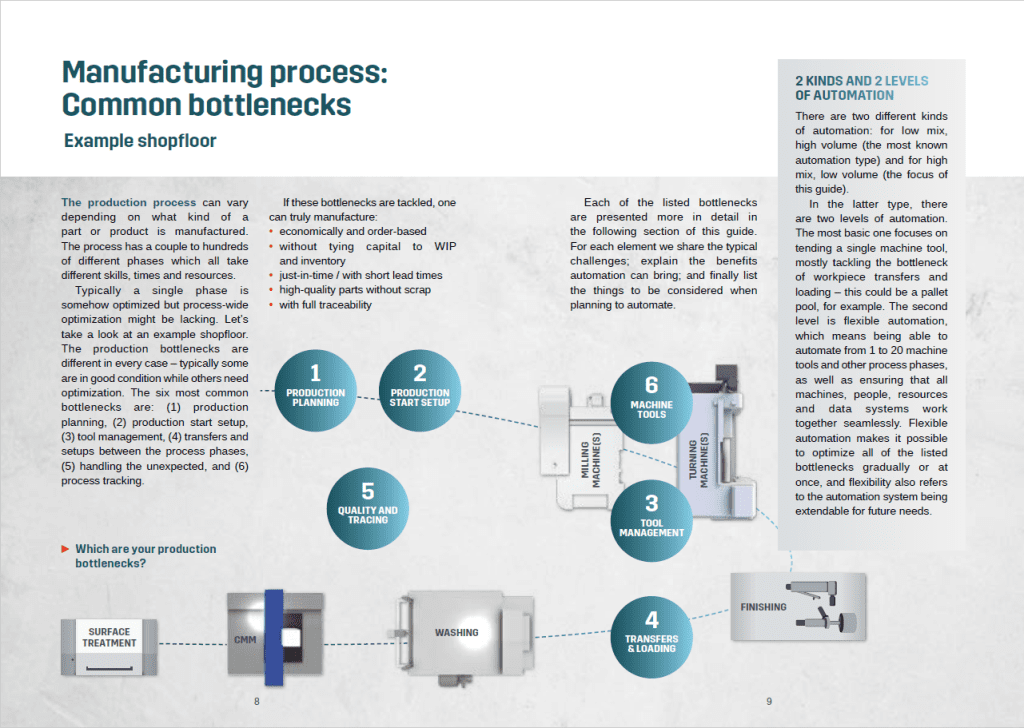

- Download our automation guide for a practical, step-by-step instructions on how to improve and automate metalworking batch manufacturing – including supportive processes and devices. There is a snippet of the guide next to this text.

- Enjoy a webinar recording where our MMS product manager Janne Kivinen explains the six solution blocks of economic small batch manufacturing.

- Contact your local Fastems representative. Developing a well-working automation system requires always case-by-case evaluation, discussions and concepting. That journey can begin today!

Solution Finder

Use the below selections to browse our automation solution platforms and get a head start for discussion with your local Fastems representative:

Filter by

Machine tool or process type

Filter by

Qty of machines

Tired of browsing?

Give us as a call or send and email for any questions you might have!

"*" indicates required fields