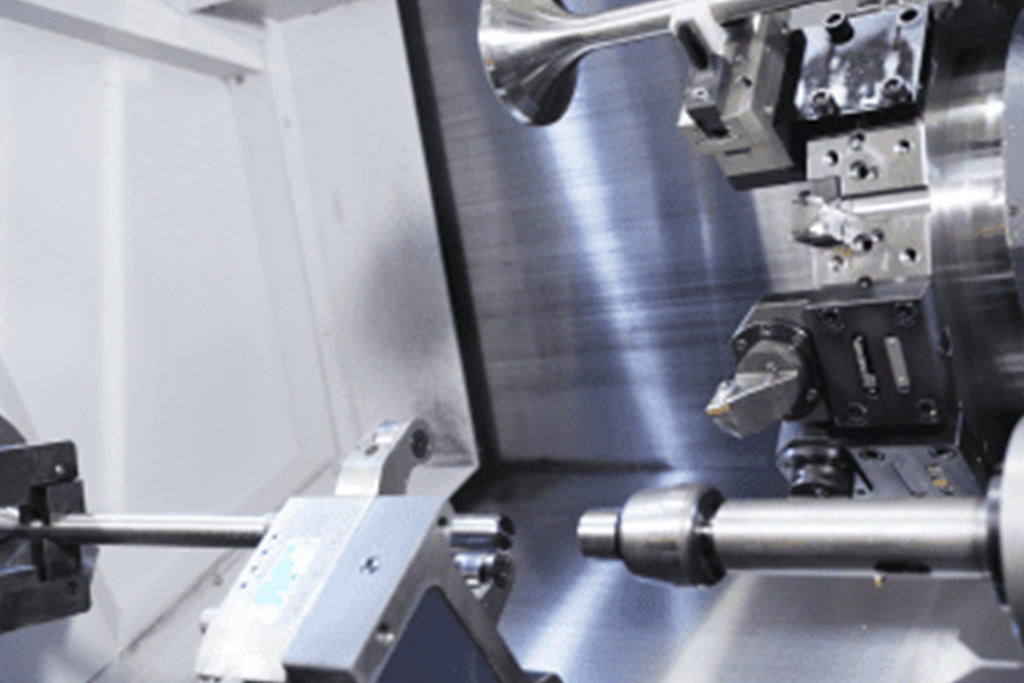

CNC Automation for Turning Machines

Flexible And Profitable Variable Batch Production with Turning Machines

Fastems has long experience in automating different kinds of turning machines and machining centers used in variable batch production, where the key is to combine efficiency with flexibility.

We have solutions from single machine cells to multi-machine automation systems. With Fastems, you can also integrate your supportive processes like measuring, washing or marking the be a part of the automated production, managed with our industry-leading control software MMS. Our solutions are also extendable and modifiable.

Single spindle turning

Single spindle turning operations can be easily automated with a robot. The robot picks up the raw material from the material station and loads the machine spindle. After the machining is ready for the first operation, the part is often turned and loaded again to the machine tool to finish the other end, to be again unloaded after the machining. The part is often unloaded back to the material station, or it is taken to an auxiliary manufacturing process, such as washing or measuring.

For a case example see Merkische Werk

Dual spindle turning

Dual spindle turning operations can be very efficient, providing a way to manufacture the parts running simultaneously with both main- and sub-spindles. It is useful to be able to run your dual spindle machine tool in many ways. As an example, running the dual spindle from sub-to-main spindle can yield some extra room for the revolver tools with some turning machines. Sometimes the machine can feature a milling spindle as well.

For a case example, see Buck CNC Technik

Turning from bars

Making smaller parts from a bar is a quite common way to build production buffer to a turning machine. This is often realized with a dedicated bar-feeder that is integrated to the machine tool. Now it is also possible to load a longer blank with a robot, and realize this kind of buffering with a dual-spindle machine tool, thus gaining bar-feeding benefits without a dedicated bar-feeder.

Higher revenue and profits with less tied capital

Improved financial results are of course driven by development in operations such as higher utilization of resources, more throughput, higher quality or more proactive production planning. The effect in short: the production achieves higher volumes and profits and operates with less money (less stocks and WIP).

Less idling, more capacity, higher quality and easier production planning

Automation transforms the daily operations making them much more productive, efficient and stable. By integrating more processes into an automation system and with the help of intelligent planning and resource management features of MMS control, the production can achieve high flow and resource efficiencies.

Happier people, customers and planet

Automation helps fighting the challenges of finding and keeping skilled labor and being able to deliver quality on time. By increasing resource efficiency and making jobs more meaningful, safe and accessible it also supports in reaching sustainability targets.

Take these three practical steps to learn more about intelligent turning automation:

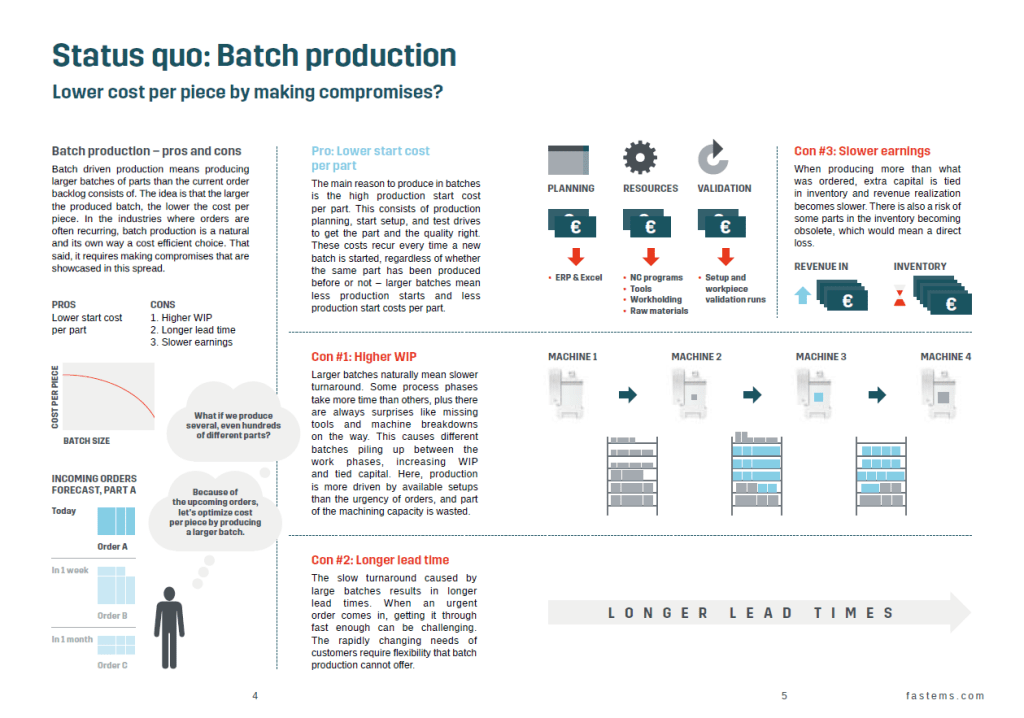

- Download our automation guide for a practical, step-by-step instructions on how to improve and automate metalworking batch manufacturing. There is a snippet of the guide next to this text.

- Enjoy a webinar recording where our MMS product manager Janne Kivinen explains the six solution blocks of economic small batch manufacturing.

- Contact your local Fastems representative. Developing a well-working automation system requires always case-by-case evaluation, discussions and concepting. That journey can begin today!

Filter by

Machine tool or process type

Filter by

Qty of machines

"*" indicates required fields