What Kind of Automation Fastems Supplies?

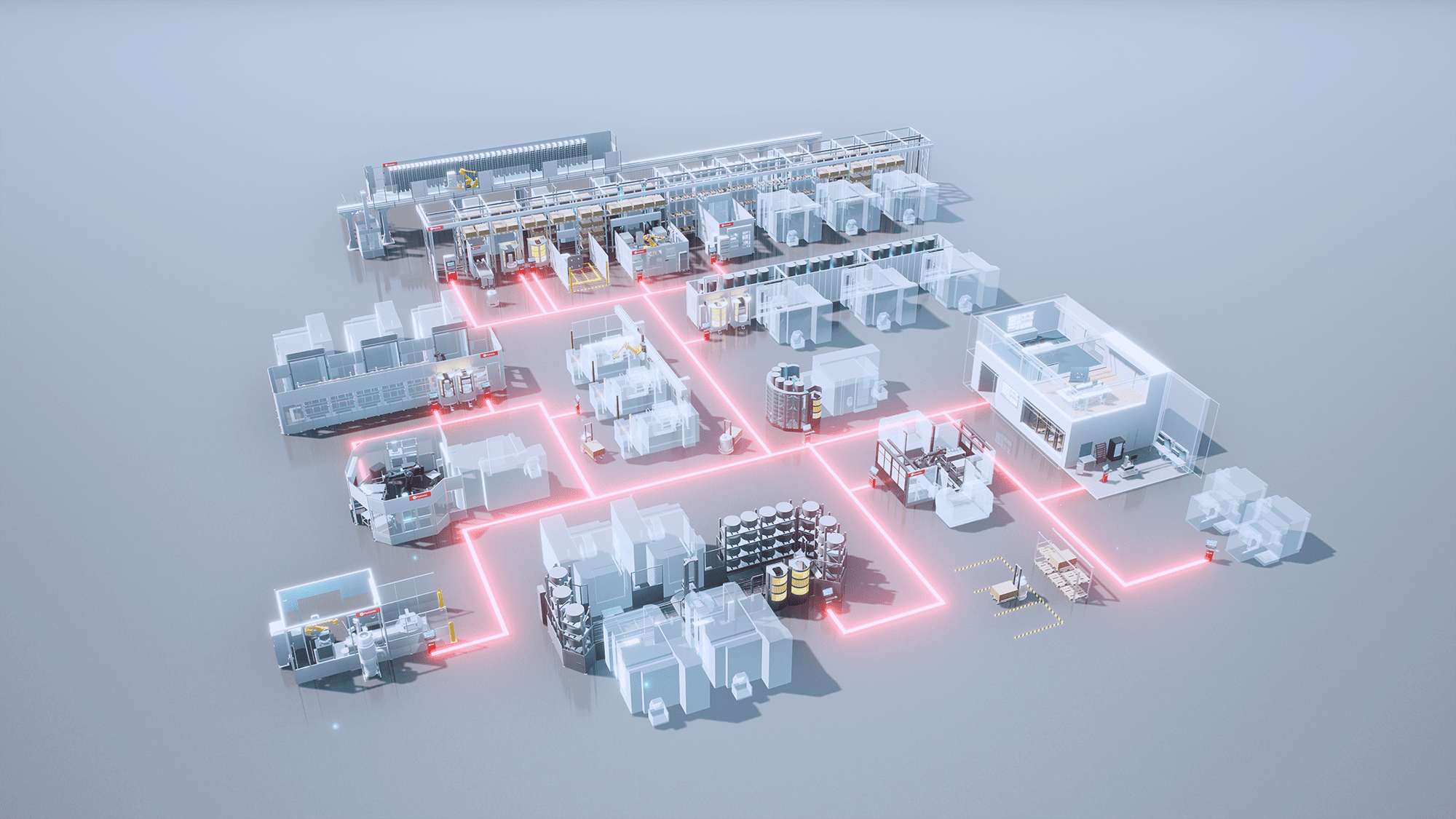

We offer a wide range of flexible manufacturing systems (FMS) for milling and turning machine tools, used in variable batch production. We also automate and integrate CNC supportive processes and supply solutions for cutting tool and tool data management. All of our systems come equipped with industry-leading control Manufacturing Management Software (MMS).

Pallet Handling Systems

Fastems supplies automation for pallet and zero-point plate machines tools in payloads of 50 – 10 000+ kg (with pallet).

These are typically 3-5 axis milling machines, machining centers, grinding machines or vertical turning machines. We offer everything from small modular systems for 1-3 machine tools to large tailored solutions with 10+ CNC machines of different kind.

Fastems can integrate your auxiliary processes like washing, measuring or marking to be part of your pallet automation system. Tool and tool data automation is also getting increasingly common. Our pallet handling systems are always equipped with the industry leading MMS control software that makes variable batch production flexible and efficient.

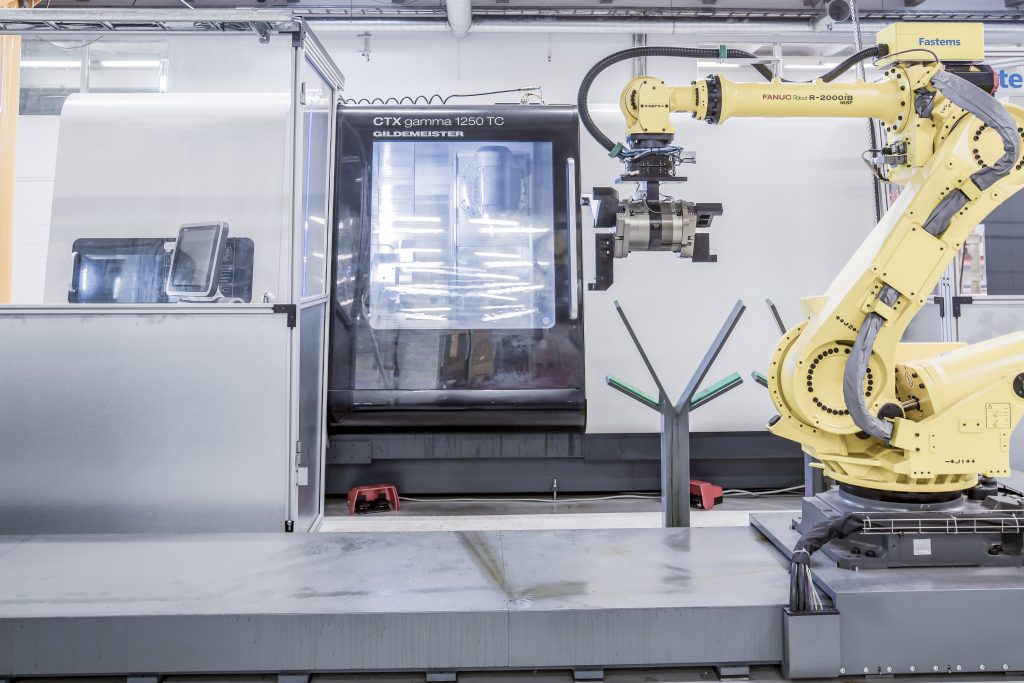

Part Handling Systems

Fastems supplies part handling automation systems in payloads of 1 – 500+ kg.

Typical automated CNC machines are single or dual spindle lathes, turn/mills, 5-axis milling machines, grinding or honing machines and more. We offer smaller systems for 1-2 lathes all the way to complex agile manufacturing systems with 10+ machines.

Fastems can integrate your auxiliary processes like washing, measuring or marking to be included in your part handling automation system. Tool and tool data automation is also getting increasingly common. Our part handling systems are always equipped with the industry leading MMS control software that makes variable batch production flexible and efficient.

CNC Supportive Process Integration

As the automation level increases, so do productivity and quality.

Fastems integrates and automates measuring, washing, marking, finishing and various other devices or processes to be part of our intelligent CNC automation systems. We also offer deburring and robotic finishing cells (RFC) and robotic systems for automated part loading to/from pallets (ALD).

Tool and tool data management are important topics especially when there are lot’s of machines and tools, materials are though and in securing the unmanned shifts form errors. The use of AGVs for pallet, workpiece or tool transferring between manufacturing operations is getting also more common and we offer integration services for them.

Solution Finder

Use the filters below to find the suitable automation solution for your manufacturing setup.

FPT – Flexible Pallet Tower

Easy plug-and-play pallet tower that supersedes traditional pallet pools and automatic pallet changers.

FPS – Flexible Pallet System

Modular FMS for multiple 4 or 5 axis milling or mill-turn machine tools with 300 to 630 mm pallets or zero-point plates.

RFC – Robotic Finishing Cell

Modular RFC, a robot-supported automation system for the flexible deburring of different workpieces

FPC – Flexible Pallet Container

Easy and extendable pallet automation solution that supersedes pallet pools and automatic pallet changers.

MLS – Multi Level System

MLS automates any machine tools for flexible manufacturing. It comes with the industry leading software, and tool automation and various auxiliary processes can be integrated.

RoboFMS – Robotic FMS

All the benefits of flexible manufacturing for 5-axis machines with no pallet.

What Kind of CNC Machines and Equipment We Automate?

Fastems can automate an exceptionally wide range of CNC machinery and supportive processes that are typically integrated into be part of a larger automation system. Automating cutting tool (data) management or an existing machine tool is also in our scope.

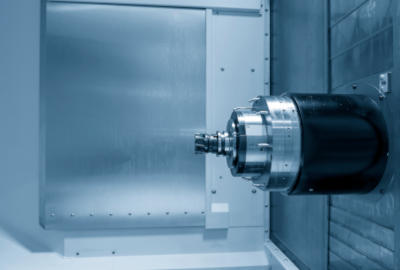

Milling and Mill-turn Machine Tools

We have solutions for 3-5-axis milling machines, mill-turns and machining centers. Pallet sizes vary from 300-1600mm+ and we also automate zero-point-plate machines.

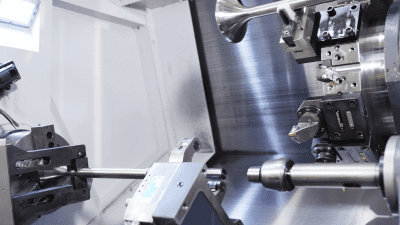

Turning and Turn-Mill Machine Tools

We automate various turning machines from single spindle and dual spindle turning machines to turn-mills. The machines can also feature a bar feeder.

Other Metalworking Processes

We automate grinding, drilling, threading, boring, honing, sawing, forming and other CNC machines. In particular, we supply robotic cells (RFC) for various finishing operations – integrated or as stand-alone.

Existing Machine Tool Automation

Depending on the CNC machine, automating already-in-production equipment is possible and profitable.

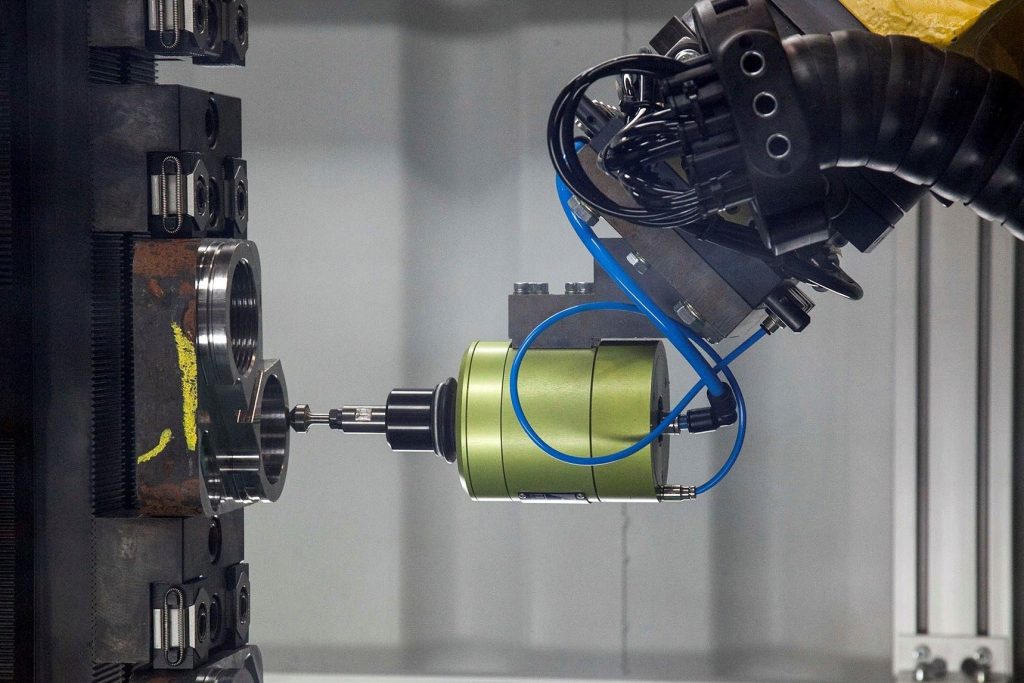

Cutting Tool Management

We supply automation for tool transfers between machines and central tool storage as well as tool off-set data management using our MMS control.

CNC Machining Supportive Operations

Fastems integrates washing, measuring, marking, deburring, polishing, grinding and other finishing, heat-treatment, assembly, welding and many other CNC supportive operations including AGV integrations.

Next steps? Download the Guide for CNC Automation!

If you are under consideration on how to reduce cost per unit, cut down setup costs, increase unmanned production or reduce WIP or inventory, this guide is the one to download.

"*" indicates required fields

Contact us

Give us a call or send an email

Contact us

"*" indicates required fields