High-Mix-Low-Volume CNC Automation Guide for Pump, Valve, Cylinder and other Fluid Manufacturers

The typical goals of fluid manufacturers include:

Producing small orders without large WIP and inventory

Shortening lead times

Reducing the amount of clampings

Optimizing cost per piece

Adapting fast to market fluctuation

How about you?

We have condensed our 40 years of automation expertise to a special guide for valve, directional valve, pump, compressor and other fluid manufacturers. The guide describes six common production bottlenecks and how to tackle them in order to produce economically in fluctuating market, and for various customer needs.

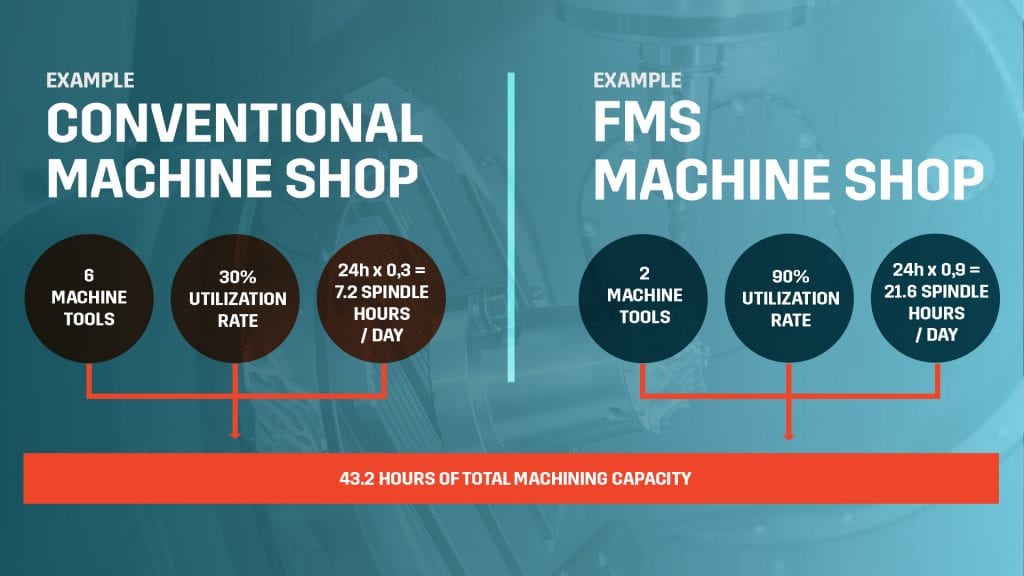

Here’s an example on how much the production figures, like utilization rate, can improve with flexible automation:

Read customer stories

Cylinders: Wärtsilä

“The benefits from the manufacturing systems include high and uniform quality, shorter delivery times, and cost efficiency.”

(project results: optimized unit cost, improved quality and traceability, less WIP)

Read more

Hydraulics: Sant Hydraulic

“There are 1440 minutes in a day and the average cutting time of our machine tools is now 1420 minutes. We have reached world class levels of production.”

(project results: lower unit cost with lower batch sizes, shorter production start setup times)

Read more

Pumps: Robuschi

“We can manufacture parts in single batches now!“

(project results: shorter production start setup, less machine dedication, less transfers, lower unit cost per piece)

Read more

Valves: Högfors

“Now, it is profitable to manufacture small batches and even single parts, because the FMS reduces setup times almost to zero.”

(project results: optimized unit cost, shorter lead times, faster production start setup)

Read more

Want to learn more?

Give us a call or send an email

"*" indicates required fields