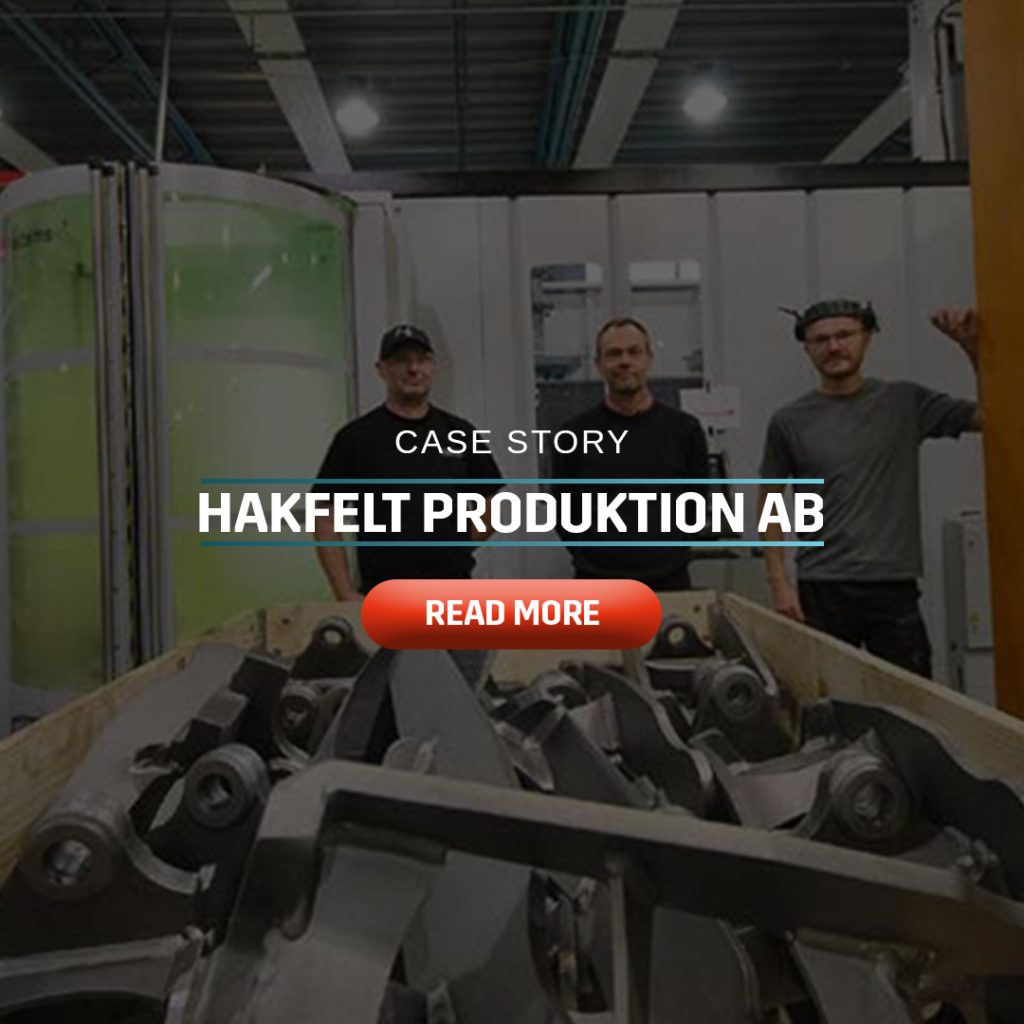

CNC Automation for Existing Machine Tools

Automating Existing Machine Tools

Enjoy the Benefits of Automation Without Acquiring New CNC Machines

Did you know that automation is not the privilege of only new machine tool investments? There are plenty of situations where automating your current machine tools pays off, and with the right partner, the navigation through the necessary technical landscape around e.g. the machine tool interfacing and safety matters can be carried out efficiently and with minimal interruption in your production.

The usual drivers for existing machine tool automation include:

- The need for more production capacity

- The need to improve production profitability, lead times, quality or for example employee engagement

- Aging automation hardware malfunctions and/or is a business risk.

What Kind of Existing Machine Tool Setups Do We Automate?

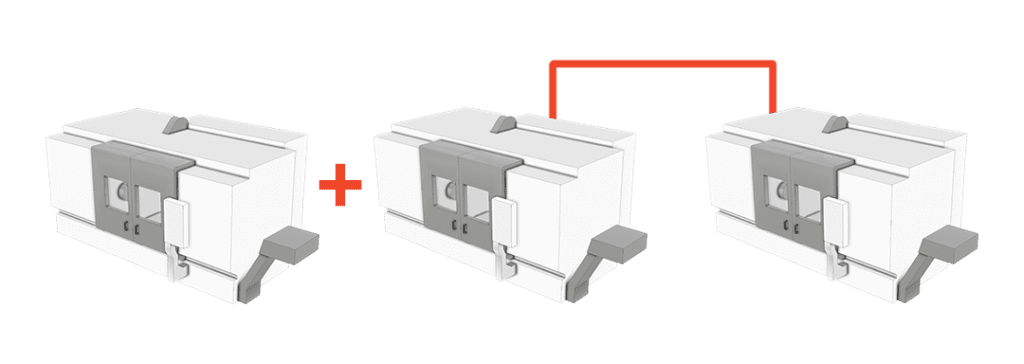

Available automation options are naturally linked with the setup of machine(s) considered to be automated. The main categories for automating existing machine tools are the fully stand-alone machines; machine tools in existing systems, and hybrid solutions with both, stand-alone and existing systems.

Plan, control and monitor work cells

Automating Existing Stand-alone Machines

It is possible to automate existing stand-alone machines around physical transfers of pallets or workpieces to machine table or chuck. In addition to this, production planning and resource management features can be automated also without any interface connection to the machine tool.

Bring higher efficiency to existing systems

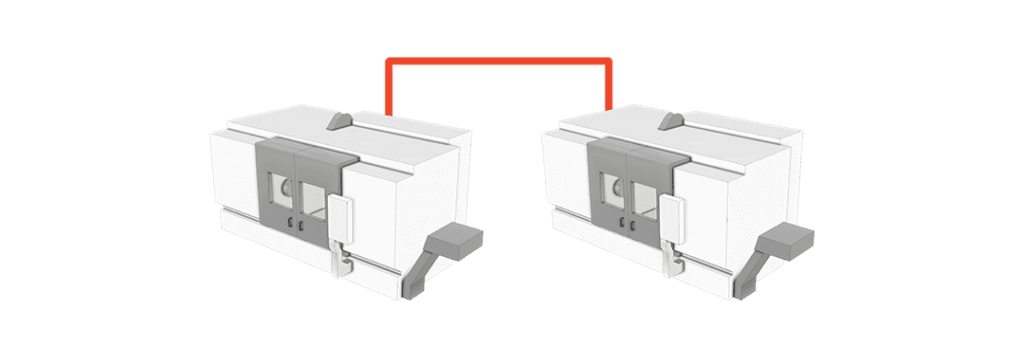

Automating Machine Tools in Existing Systems

The machine tools in existing automation systems can be automated physically, with MMS control and 3rd party hardware, or in terms of production planning and resource management only.

Complexity is not an issue

Automating Machine Tools in Hybrid Systems

We have also helped larger factories with hybrid systems comprising of both stand-alone machine tools and machine tools in existing systems, to get the same benefits of automation as they would if investing in new machinery.

The Benefits of Automating Your Existing Machine Tools

It does not matter whether one is talking about the automation of new or existing machine tools: the tremendous benefits automation brings apply in both. Take a look how how automation transforms operations, financials and customer and employee satisfaction:

Operational Excellence

Automating existing machine tools results in less idle times, higher and more stable quality, more effective and integrated processes, automated production planning, resource management and unmanned production – all factors comprising into operational excellence.

Happy Customers And Employees

High and constant quality combined with fast and reliable lead times ensure that the customers are supplied with the right parts at the right time and with the right measures while keeping you profitable. In addition to this, intelligent automation results in more meaningful and safe work environment for the operators.

Financial Performance

Automation enables factors such as higher production capacity; decreased labor and machine tool investment costs per part, and decreased work-in-capital.

1. Project Management

What comes to existing machine tool automation, we see the project as a two-folded entity, consisting of the pre–study phase and the actual project phase. Based on the pre-study phase, the opportunities and the business case are carefully defined, and the final decision to move forward is based on the findings of this first phase.

For the actual project phase, the responsibilities of the three parties (the manufacturer, automation provider and the machine tool builder or dealer) are carefully defined; the project team is selected, and the schedule of the project with the possible production disturbances are agreed on.

2. Interfacing Options

Probably the most complex and situation-bound part of the existing machine tool automation project is to plan and execute the interfacing of the machine tools. Based on the manufacturer’s need and desired outcome of the project, as well as on the current setup on the shop floor, the level of interfacing is carefully selected and implemented. There are three levels of interfacing available: no interface, standard interface and advanced interface.

3. Interface Development

For automating existing machine tools, interface development is crucial. Our interface development process is carried out in six steps: collection of machine tool data; clarification of machine tool readiness for interfacing; pre-study on hardware, software and safety; interface definition with manufacturer, MTB and automation provider; interface development, and pre-testing or simulating at the manufacturer or MTB if necessary.

4. Physical Changes and Safety

When automating, the physical changes to the machine tools as well as the required safety leveles vary case by case. Relevant factors are for example, whether the machine is currently integrated to an automation system or if it has an automatic pallet changer (APC). The physical changes on machine tools are always the responsibility of the machine tool builder.

Solution Finder

You can filter our automation solutions by utilizing our solution finder below. If you didn’t find what you were looking for, not to worry – we are an open integrator and therefore able to automate almost any machine tool!

Didn’t find what you were looking for or have questions? Contact our professionals!

Filter by

Machine tool or process type

Filter by

Qty of machines

"*" indicates required fields