CNC Automation for Aerospace & Defense Industries

Profitable and Flexible CNC Manufacturing for Aerospace & Defense industries

For decades, companies like BAE, Lockheed Martin, SKF and MTU as well as many tier-level suppliers have worked together with Fastems for leading CNC automation solutions in aersopace and defense industries. Our automation enables high spindle hours and resource utilization, fast and reliable lead times, constant quality, full traceability and proactive production planning. Want to know how? Download our CNC automation guide from below!

Get your free CNC automation guide

CNC automation applications include parts for:

- Jet engines (e.g. turbine blades or axels)

- Fuselage parts

- Wing ribs/skeletons

- Landing gear

- Helicopters and drones

- Armored vehicles

- Aerospace hydraulics and actuation

- Aircraft brake components

Production Challenges and Automation Benefits:

- More customization and amount of variants

- Shorter lead times and planning horizon

- Costs & tied capital reduction

- Demand variance

- Traceability needs

- Availability of workers

- Constant quality

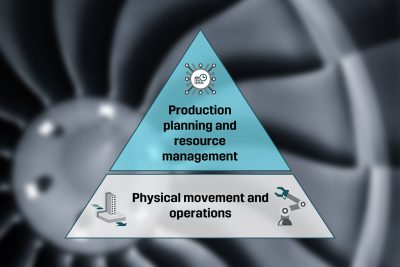

Automate Production – Not Just Movement

Learn how to get the most out of your CNC machines and other equipment by applying batch production automation best practices summarized below:

- Stabilize and integrate manufacturing process steps

- Automate physical part transfers throughout the value chain

- Benefit from automated, intelligent production planning software

Solution Finder

Use the filters below to find the suitable automation solution for your manufacturing setup. Please note Fastems is an open integrator and therefore able to integrate almost any machine tool in the world, so if you can’t find what you were looking for, just contact us directly!

Filter by

Machine tool or process type

Filter by

Qty of machines

"*" indicates required fields