TeknoComp’s Automated 5-Axis Machining Center Delivers Significant Efficiency Gains

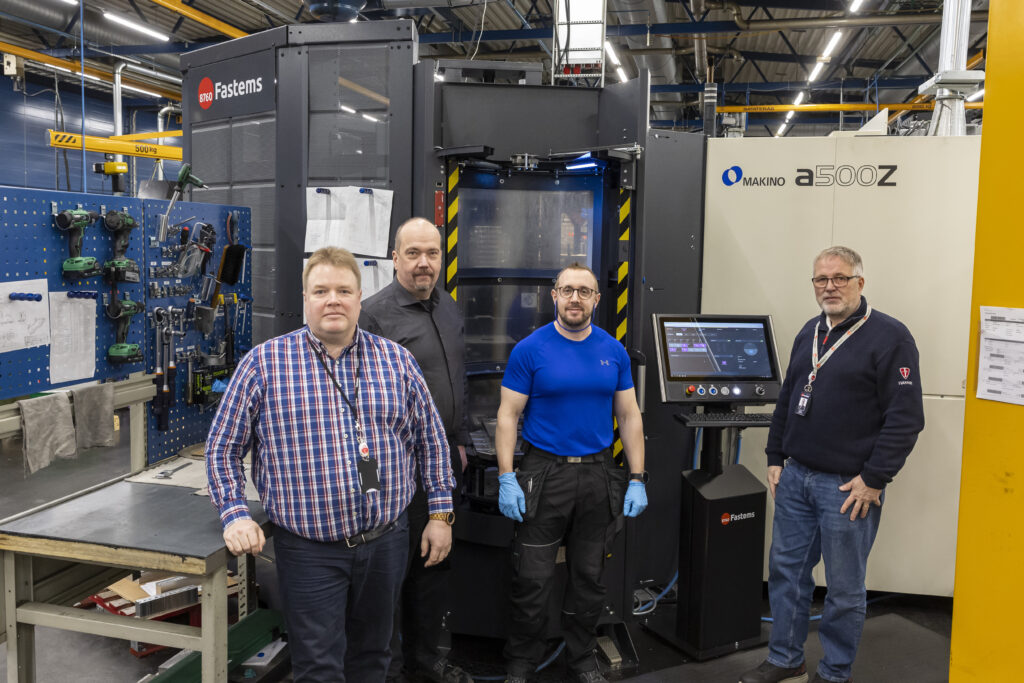

“We develop our manufacturing capabilities based on our customers’ needs. Our strength lies in machining highly demanding parts in small and medium batches – cost-effectively,” describes Hannu Voltti, the CEO of a Finnish contract manufacturer TeknoComp. Located in Ruukki business park in Siikajoki village, the company supplies precision mechanical components to manufacturers of medical devices, optomechanics, network devices, and electronics testing equipment. The cornerstones of TeknoComp’s business are skilled employees, certified quality, and versatile machining capabilities – from prototype manufacturing to medium-sized batches.

After our manned weekday and weekend shifts, we run lights out during nights. Compared to our four-axis machines, the efficiency of this system is multiple times higher.

Taking the Most Out of 5-Axis Technology with Automation

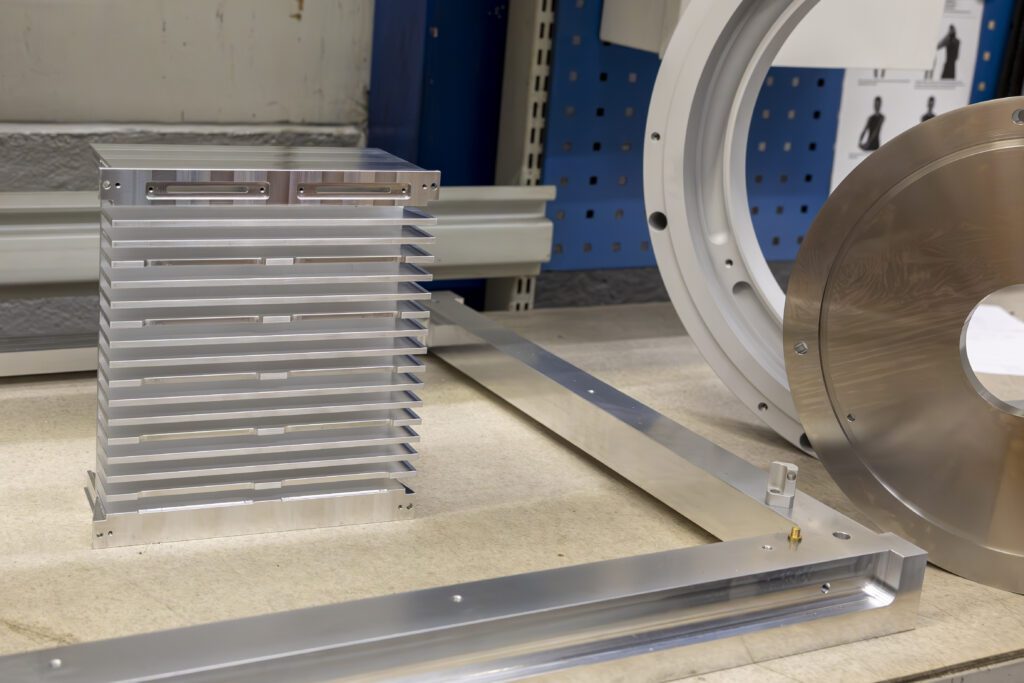

TeknoComp’s machine fleet includes a total of 25 vertical and horizontal milling machines, and multi-tasking lathes. The machined sizes range from two millimeters to over half a meter, and parts are machined from aluminum, copper alloys, plastic, steels, and titanium. The precision level is extremely high and geometries challenging in most of the components, meaning that machinists are constantly needed for machine setups, part re-clamping and quality checks.

To power up the production of challenging parts, TeknoComp decided to invest in a 5-axis machining center and automation. The goal was to run a wide variety of parts with a single clamping, regardless of batch size.

“We found a suitable 5-axis Makino machining center from Cron-Tek to run our part portfolio – and also invested in pallets at the same time. However, such an efficient machine cannot be well utilized without automation,” says Voltti. “In a country like Finland, automation is a necessity to be able to compete in international markets.”

Our machining times vary between five-minute prototype runs to two hour production batches. We just pre-load jobs into FPT, and the system changes pallets in a few seconds.

Selecting Fastems as Automation Partner

After comparing several options, TeknoComp chose Fastems as their automation partner. Voltti states, “Our customers’ needs define how we develop our production, and we wanted our automation partner to be capable of integrating any machine type and brand we might ever need. Fastems has a wide range of automation solutions for both milling and turning machining processes, and the same MMS control is used in every system. We can plan, run, and monitor our production with a single software, no matter which Fastems systems we would have on our shopfloor.”

To automate their 5-axis Makino, TecnoComp selected the compact and flexible pallet system, Flexible Pallet Tower (FPT). FPT is a factory-tested and fully assembled pallet tower with ready interfaces for hundreds of different machine tools. The system accommodates up to 18 pallets and enables long unmanned machining periods.

“Machining times with our Makino vary between five-minute prototype runs to two hour production batches. We pre-load jobs into FPT, and the system changes pallet from the machine tool in a few seconds. After our two manned weekday shifts and 12-hour manned weekend shifts, we run lights out during nights. Compared to our four-axis machines, the efficiency of this system is multiple times higher.”

Once a part has been introduced into the system, it can be machined with zero setup time.

Flexible System Helps Meet the Customer Needs Better

Fastems’ automation systems are designed for today’s manufacturers – the production must be flexible even with small batch sizes and varying demand. Machinist Mikko Hinkula explains, “We input our orders directly into the production control MMS, which then schedules production for just-in-time deliveries. The system knows which resources are needed for each of our parts. After creating a production schedule, it guides which raw materials, tools and NC-programs we need to prepare by when. If a necessary resource is missing when the machining should begin, MMS re-schedules production and takes another job first. This avoids unnecessary machine stops and maximizes spindle utilization.”

The system saves time from machinists – on the so-called ‘automated side’ at TeknoComp, one person can take care of four machines at once. On the ‘non-automated side’, each machine typically requires its own machinist. “Flexible automation allows us to plan our work better – we don’t need to continuously act to keep the machine running,” says Hinkula.

“Our FPT is popular – everyone wants to work with this system! We are constantly bringing in new jobs, as even the smallest batches can be run quickly and efficiently. Once a part has been introduced into the system, it can be machined with zero setup time,” smiles Voltti. “It’s also great that we can produce just-in-time and don’t need to run parts into inventory. Order backlog of maximum four weeks is nothing strange for a contract manufacturer like us, and it wouldn’t be sustainable to keep high inventory values.”

We input our orders directly into the production control MMS, which then schedules production for just-in-time deliveries.

Listening to Customers and Increasing Efficiency

TeknoComp continues to bring new orders into FPT from their old 3 and 4 axis machines – and maximize unmanned production capacity by filling the remaining six pallet places.

In the future, the company plans to explore the flexible automation possibilities for their vertical machines. “We don’t have robotics on the floor yet, and we would like to run small batches more efficiently with our multi-tasking lathes as well,” says Voltti. “Horizontal machining centers will also be renewed at some point – probably equipped with a flexible automation system. However, it all depends on our customers: we carefully listen to what they need and develop our capabilities accordingly!”