This article was originally published in the June 2020 issue of Maskinoperatören’s digital newspaper.

Hands-on advantages for the shop floor

The machining and automation industries have evolved quite a bit in the past 20 years. Before then, operations were considered productive if machine tools were spinning at the maximum amount each day, week and year. The more spindle hours, the more revenue. Batch sizes were large, and product variation was quite stable.

During the last years however, customer needs have gradually changed, which has also affected the business of manufacturers. Maybe you’ve noticed some of the changes on your shop floor? There is a growing need for different batch size production, and manufacturing work pieces to storage is no longer the safest and or most sensible option. This shift and change in manufacturing trends demands investments in new manufacturing technology. And while the practical benefits of such investments may not always be self-evident, they are strongly visible on the factory floor. Oftentimes, the key factor of new technologies is software, which is why we want to uncover the hands-on advantages of new ways of machining.

Running your shop floor with excel spreadsheets?

There are still many companies who manage production work with excel spreadsheets distributed to the factory floor as paper documents. The master data can be handled in other spreadsheets or through an ERP. Now, if a company produces large batches in high volume and the product variation is fixed and limited, using spreadsheets might actually be just enough to make it work in that environment. Here the manual work is manageable, and operators get simple work lists. However, if and when that company’s customers’ buying needs change, the production might face new challenges. In this case, the process must be re-evaluated, and old ways might need reviewing. When production planning becomes more complex, so do the work lists, production documents and work in general. This makes it harder to maintain transparency, keep plans and people up to date, as well as employee motivation levels running high. Luckily, new technology can help meet the new operation needs in a flexible and easy way.

Everything under one control = being in control of everything at all times

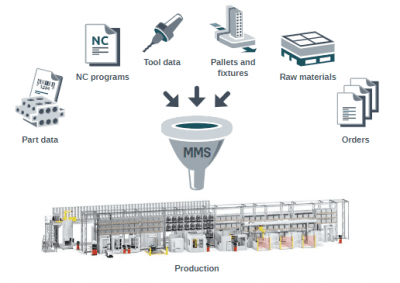

From the perspective of the shop floor, important aspects include knowing where and when to take materials, what tasks need to be done and during what shifts, what kind of tools are needed and when, and whether all documents and instructions are available and up-to-date. With these factors in mind, when production becomes more complex and fast-paced it becomes even more important to keep the shop floor on top of the latest information. If a company decides to invest in new software that can bring transparency, automatic scheduling and resource management under one control, the factory can operate in a smoother way even if changes occur.

From the perspective of the shop floor, being in control means knowing where and when to take materials, what tasks need to be done and during what shifts, what kind of tools are needed and when, and whether all documents and instructions are available and up-to-date.

Optimize production queues and ease the work of the shop floor operators

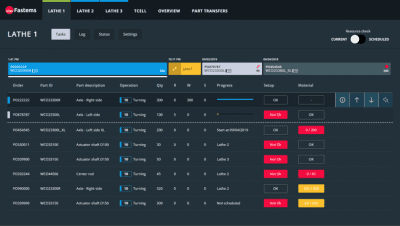

Without centralized production planning software, there is usually a lot of paper work, such as orders and drawings, physically attached to the work pieces and materials. A change in an order can cause a hassle and requires a person to manually go and deliver the updated documents. The operators might complete the NC programs themselves or they might be done in the back office and transferred to the machine with a USB stick. With software however, it is possible to add and distribute NC programs automatically to the right machines without extra efforts like programming the machines personally or using a data transfer via USB. In addition, orders can be handled automatically, and the software does the production planning in real-time. This eases the work of both the production planner and operator. Even if changes occur, the software will optimize production queues.

Centralized and objective methods are needed

Of course, some operators do an excellent job of programming the NC programs directly to the machine, and they may create work lists out of memory and habit. For the operator, that might feel most suitable option because it is based on personal preferences. From the perspective of the company and production planning as a whole however, centralized and objective methods are needed. Luckily, software can make prioritized work lists that take into consideration all orders and resources, and automatically create the best production plans highlighting the big picture. For production overall, this is a critical benefit.

The operator might need to adjust setups more often than preferred, but on the other hand, it’s what’s best for the overall production scheme. The right machines and tools are reserved for the operator at the right time, because the journey of the workpiece is clearly planned with the software. The operator can trust that work lists are always in order and other phases, such as washing, finishing, quality and inspection, are optimally planned as well. If changes occur, work lists are automatically optimized and made perfect for the operator. This means being able to concentrate on the quality of work while leaving the ambiguous and stressful tasks for the software to handle.

Intelligent Manufacturing Management Software by Fastems

There are various manufacturing management and production planning software programs in the market. Fastems offers its Manufacturing Management Software (MMS), which aims to bring transparency to all operations. This means everything in the factory from shop floor to the office, which in turn eases work around production planning and execution. In addition to the comprehensive and capable software, Fastems also provides intelligent automation solutions for part and pallet handling.

With Fastems’ control panel for the MMS software, the angle of the monitor and the height of the worktable can be easily adjusted to according to personal preferences.

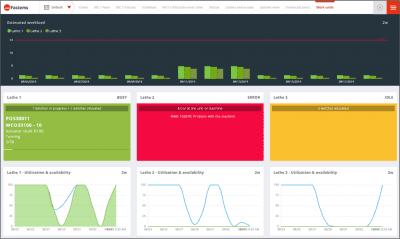

MMS provides beneficial production information, such as KPIs, which can be viewed in all areas of the factory in real-time. The company also provides a control panel, the Station Commander, which is specifically designed for convenient operation around production execution. One can adjust the angle of the monitor and the height of the worktable easily.

KPIs can be viewed in real-time and the information can be presented on screens in different parts of the factory and offices available for everyone.

One major MMS benefit is central tool management. Instead of having to input tool pre-set data manually to the machines each time, MMS gathers and passes on the information after one single input. MMS calculates the duration of the tool usage time and predicts when the tools and inserts need to be changed or updated. This means operators don’t need to manually check the state of the tools and unwanted tool breaks are avoided. This also results in an increase of machining quality.

MMS creates prioritized work lists for the operators, which take into consideration all the orders and resources. Work lists are always automatically updated and optimized when changes occur.

Remote and on-site training opportunities for a safe shop floor ramp-up

In addition to providing intelligent manufacturing management software for orchestrating the production, Fastems can offer digital means to get ready for a new production process before ramping up the software or automation solutions. Fastems offers both on-site and remote training possibilities before the ramp-up, which eases the transition to using new technologies. With remote training tools, employees can train and test the MMS software and automation systems safely before having the real software or system in use. The remote training tools are available also after ramp-up. The best part is that the training content is personalized and tailored based on the customer’s individual configurations.

One thing that is inevitable, is change. The manufacturing industry and especially customer business trends are in constant development, so having the right set-up to keep up with changes is important – on and off the shop floor. While new technologies are sometimes seen as modern vanity or unnecessity, in reality they are often the essential for creating a flexible and supreme way of manufacturing and producing.

This article was originally published in the June 2020 issue of Maskinoperatören’s digital newspaper.