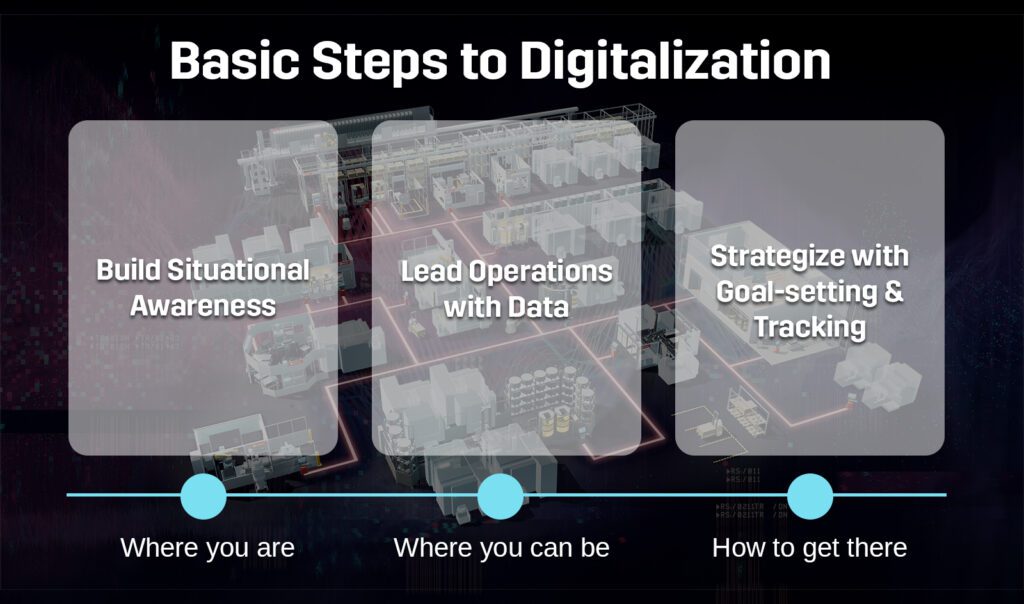

The journey from automation to digitalization is a transformative process that can significantly enhance the efficiency and productivity of your manufacturing operations. This journey can be broken down into three critical steps:

- Building situational awareness

- Leading operations with data

- Strategizing with goal-setting and tracking. Each step addresses specific pain points and paves the way for a fully digitalized production environment.

Step 1: Build Situational Awareness

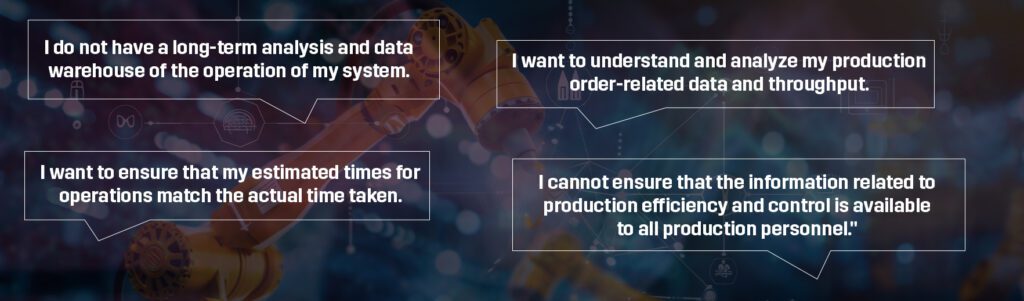

When starting with digitalization, the general pain points we hear are usually the following:

For companies that have not had any level of digitalization, starting the journey might feel overwhelming. However, the very first step, but also one of the key purposes to digitalization, is to have one centralized location to store all production data. This helps make it easier for employees, from production managers to operators, to oversee and manage production and machining activities. Not yet mentioning data analytic capabilities, having situation awareness can already bring multiple values for production development work. Information such as whether a machine has been running as planned or if there have been unplanned stops would help employees react to the problems timely, reduce machine downtime, and improve overall production performance.

Therefore, to get started with digitalization, focus on building situational awareness for your production. This can be achieved by using a centralized dashboard to provide a comprehensive overview of production status. This dashboard should integrate data from all production stages and highlight ongoing issues and their resolution status. If possible, also implement automated notifications and alerts to keep you informed about the status of critical issues and the progress of their resolution.

Step 2: Lead Operations with Data

Customer pain points at this stage include:

Leading operations with data involves transitioning from manual, paper-based processes to digital systems that provide real-time insights and analytics. To achieve this, implementing a Manufacturing Execution System (MES) that digitalizes workflows and automates data collection is encouraged, eliminating the need for paper and excel-based tracking. In addition, based on the configuration, a MES solution can also provide:

- Inventory management with real-time tracking of materials and resources

- NC program management that ensures the correct versions are deployed to the right machines

- Tool management capabilities that offer visibility into tool availability and usage

This again goes back to the previous point of having a centralized platform for storing data and processing orders, making it easy for employees to access and utilize production resource more efficiently. Especially for non-automated or standalone machine tools and operations, having a platform that connects them to the overall production management would bring seamlessness to the overall manufacturing process. You are now leading your operations with data.

Step 3: Strategize with Goal-setting & Tracking

At this stage of your journey, you might find yourself asking these questions:

After being able to track and control your production activities, you can leverage the information further by setting measurable objectives and continuously monitoring progress of your manufacturing. Once you are ready with step 2, you already have a good data foundation for long-term analysis and trend identification, therefore makes a strong basis for production development, based on data. At this point, you can use business intelligence tools that analyze your manufacturing thoroughly, providing detailed reports and dashboards that offer insights into production performance and throughput, identifying bottlenecks, and optimizing order flows. The tool should also allow for seamless information sharing among production personnel, making sure they are informed about production efficiency and control measures.

Conclusion

The path from automation to digitalization involves building situational awareness, leading operations with data, and strategizing with goal-setting and tracking. By addressing specific pain points at each step, you can create a more efficient, responsive, and data-driven production environment. Embracing digitalization not only streamlines operations but also positions your manufacturing processes for long-term success in an increasingly competitive landscape.

Learn How to Start Your Digital Manufacturing Journey in AMB and IMTS 2024!

Joining in AMB in Stuttgart or IMTS in Chicago in September? Join our “Digital Journey Wednesday” 11 September or reserve your own demo to learn more about this topic and see how flexible automation works in practice!

11 SEPTEMBER 2024

IMTS: Digital Journey Wednesday

Join our educational sessions in IMTS to advance in your Digital Manufacturing journey, no matter where you currently are. Learn and see the demos of our digital solutions that cater specifically to your production needs, using the existing resources that you already have!

11 SEPTEMBER 2024

AMB: Digital Journey Wednesday

In AMB we will walk you through the digital manufacturing journey and demonstrate our digital solutions, assisting you at every steo of the way. Join the sessions in the booth program or book your own demo!