The red light of the machine tool is flashing, the spindle is not running – is your machine waiting for a cutting tool? With the increasing complexity of machining and an escalating part mix, cutting tool management plays an even more important role than before. In the long run, every minute adds up to affect a shop’s productivity. This means that machine stops caused by missing tools, tool loading errors or worn out tools are something that have to be minimized. In this blog series we present the math behind productivity related to cutting tools and explain how to implement the best tool management practices in four steps – today focusing on the very first of them.

First, let’s look at machine waiting time. Here’s an example of how waiting times affect productivity:

A company has 4 machine tools,

each runs 6,000 hours a year (24,000 machining hours a year).

There is an average of 4 hourly tool changes per machine (96,000 tool changes a year).

The operator is immediately available 90% of the time,

meaning that in 10% of the tool changes there is a waiting time (=9,600 tool changes with waiting time).

If the waiting time is averagely 10 minutes, it would mean 1,600 hours of yearly waiting time.

What is the cost of 1,600 idle hours?

From reactive to predictive

The magic word here is predictability: if the operator doesn’t know the cutting tool needs in advance, the machine continuously needs to be watched for possible interruptions. That said, even with the most careful surveillance, there will be times when no one is available immediately. The operator needs to be able to see the upcoming tool needs in advance, so that he can prepare tools BEFOREHAND.

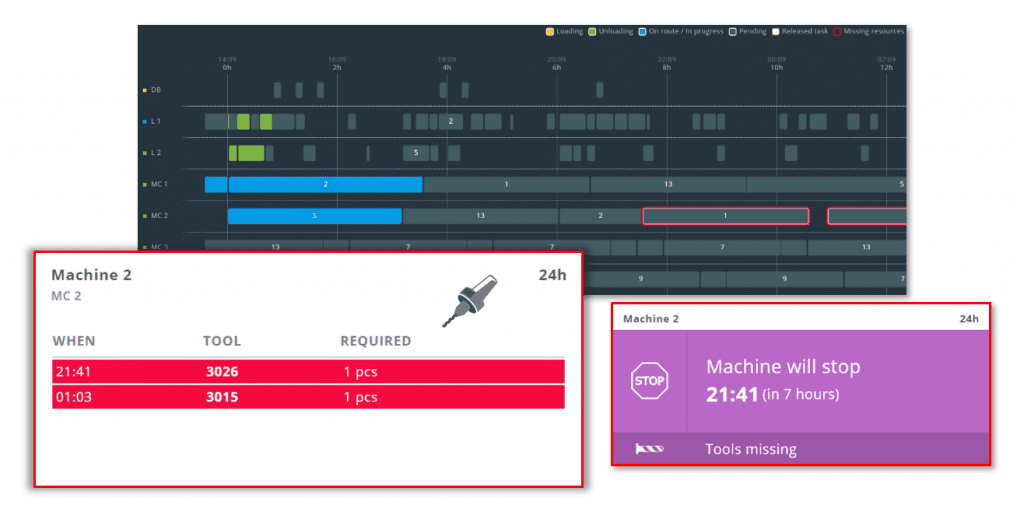

Intelligent production control software, like Fastems’ MMS, is able to plan the production ahead based on REAL-TIME DATA on NC programs, cutting tools, machines and other resources. The system informs operators ahead of time of upcoming cutting tool needs. When is a tool needed and where? MMS has visibility 96 hours ahead and it alerts if a machine is about to stop because of a tool shortage.

The first step in implementing the best tool management practices is to move from reactive to predictive working. With predictive tool management, machine utilization is significantly higher, personnel resources can be used wiser and operators can plan their work better. 90% of Fastems’ customers have performed this step, and it has played a major role in many productivity leaps.

Our next cutting tool related post focuses on the second step to achieving the best tool management practices: how to minimize scrap and spindle crashes due to wrong cutting tool offsets. Stay tuned!

If you are interested in learning more about the best tool management practices be sure to register for our upcoming virtual seminar. This will be a day for educative webinars, video demonstrations and Q&A sessions on several productivity-related topics, including cutting tool management.