Automating Existing Machine Tools

Automation is not a privilege of new machine tool investments

Automating existing machine tools is no myth or scifi dream but a practice that Fastems has been doing for years with a clear bottom line: there are plenty of situations where automating your current machine tools pays off and there are ways to navigate through the necessary technical landscape around machine tool interfacing, table or chuck access, and safety. This page is intended as an introduction and summary around the topic. For further reading, download our free guide:

Automation Guide for Existing Machine Tools

Navigation:

1. WHAT are the available automation options for existing machine tools?

2. WHY consider automating your existing machine tools?

WHAT are the available automation options?

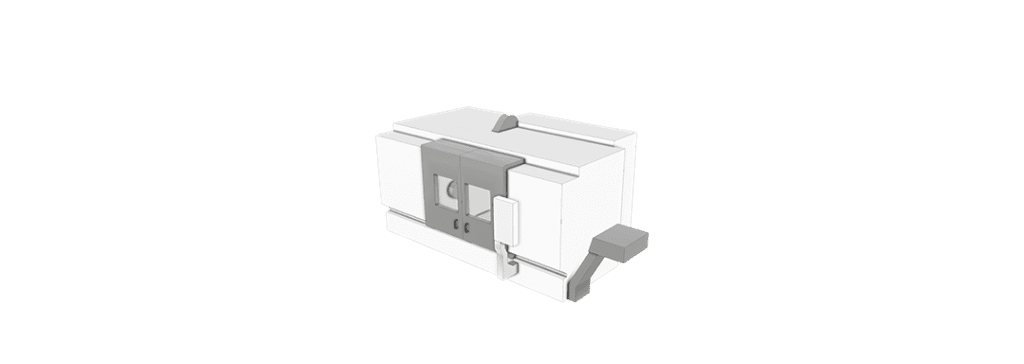

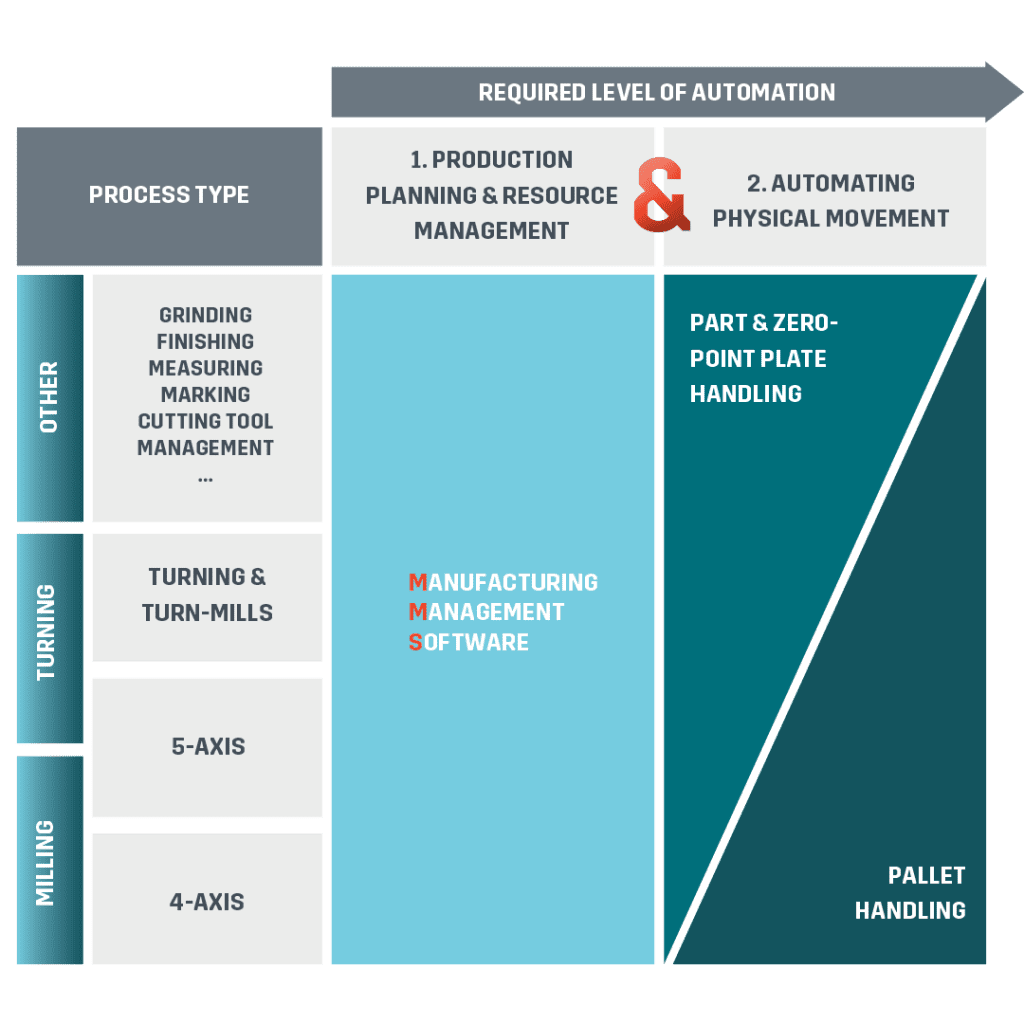

Production happens as an interplay between machinery, people and IT. They all need to work seamlessly together for the optimal results. As automation by definition means the reduction of human intervention to a process, what options are there for automating existing machine tools? As a nutshell answer, the illustration below combines process/machine types with the level of automation:

With automation hardware, the system can also execute the planned production in practice. This happens by transferring machining pallets or by direct workpiece manipulation. In addition, the system manages physical movement of tools and integration of supportive processes like deburring, washing, measuring, marking… In practice, examples vary from traditional FMS systems such as Fastems MLS to robotic solutions such as RoboCELL ONE. For completed existing machine tool automation installations, please see our customer cases by Kongsberg Automotive, Buck CNC or Supset.

Situation on the shopfloor

Available automation options are naturally linked with the setup of machine(s) considered to be automated. Here are the main categories that apply for automation.

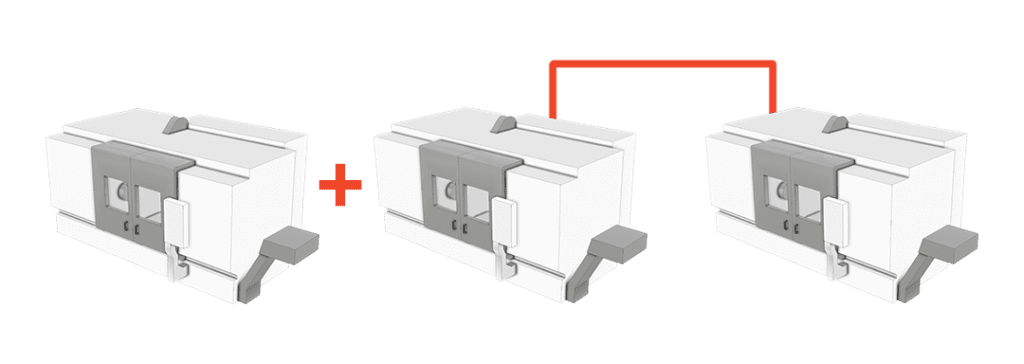

Fully stand-alone machines

Fully stand-alone machines can be automated around physical transfers of pallets or workpieces to machine table or chuck. It’s also to possible to automate production planning and resource management features without any interface connection to the machine tool.

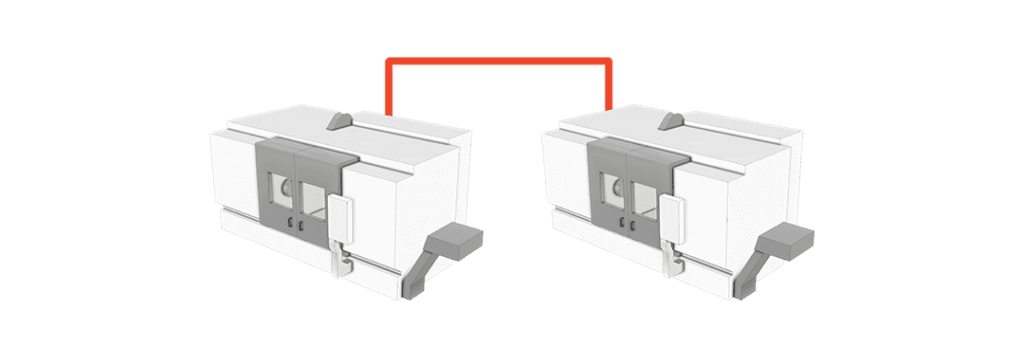

Machine tools in existing automation systems

Machine tools that are part of an existing automation system can be automated physically, with MMS control and 3rd party hardware or in terms of production planning and resource management only.

Hybrid of fully stand-alone machines and machine tools in existing automation systems

It is common for a factory with larger production and/or many machine tools to build a hybrid automation solution comprising of stand-alone machines and machine tools in existing systems.

WHY consider automating your existing machine tools?

In short, automation can help manufacturers tremendously and the benefits apply whether one is talking about automation for new or existing machine tools. We have classified the benefits to three categories explained below. What comes to existing machine tool automation, we have identified three main reasons or drivers behind them:

- More production capacity might be needed but there is not enough space for new machines or the acquirement of new machine tools is not otherwise an option;

- There might be room for improvement when it comes to production profitability, lead times, quality or employee engagement

- Aging, existing automation hardware might pose a business risk or malfunctions.

Operational excellence

Less idle times, higher and more stable quality, more effective and integrated processes, automated production planning, resource management and unmanned production are factors that result in operational excellence.

Happy customers & employees

By utilizing intelligent automation, the work of operators becomes more meaningful and safe. High and constant quality combined with fast and reliable lead times supply the customers with the right parts, right time and right measures while keeping you profitable.

Financial performance

Higher production capacity, decreased labor and machine tool investment costs per part combined with decreased work-in-capital are all benefits enabled by automation.

Project Management

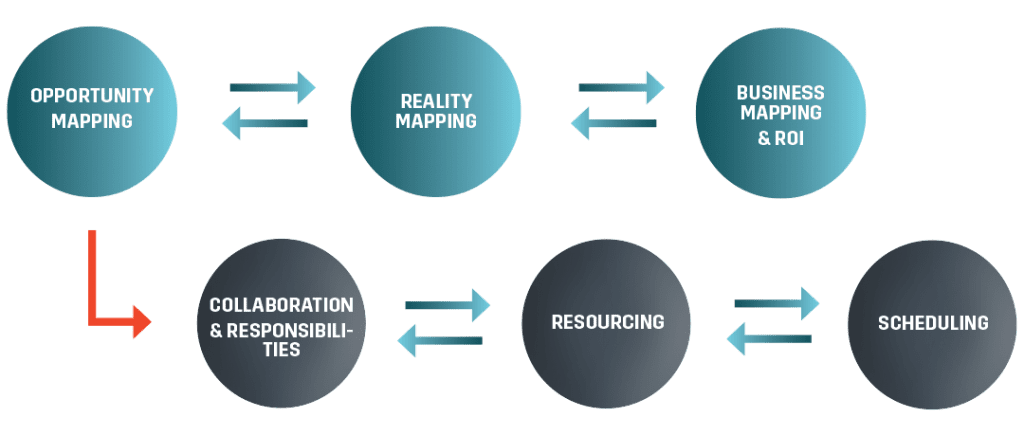

What comes to existing machine tool automation, in our view the project consists of the pre-study phase and the actual project phase, illustrated by the graph on the left. The pre-study is a key technical part of the project: based on the information collected during the pre-study, the opportunities, the situation in reality and whether or not there is a business case for the project, can be determined in detail.

When the decision to move forward has been made based on the pre-study, the project phase starts. In this part of the project entity, the responsibilities of the three parties (the manufacturer, automation provider and the machine tool builder or dealer) are carefully defined, the project team is selected, and the schedule of the project and the possible disturbances in production are agreed upon.

Interfacing

Probably the most complex and situation-bound part of the existing machine tool automation project is to plan and execute the interfacing of the machine tools. Things to consider include e.g. the quantity and type of the machines, age and the controller and machine software versions – just to name a few. Close collaboration between the machine tool builder and the automation provider is vital for the success.

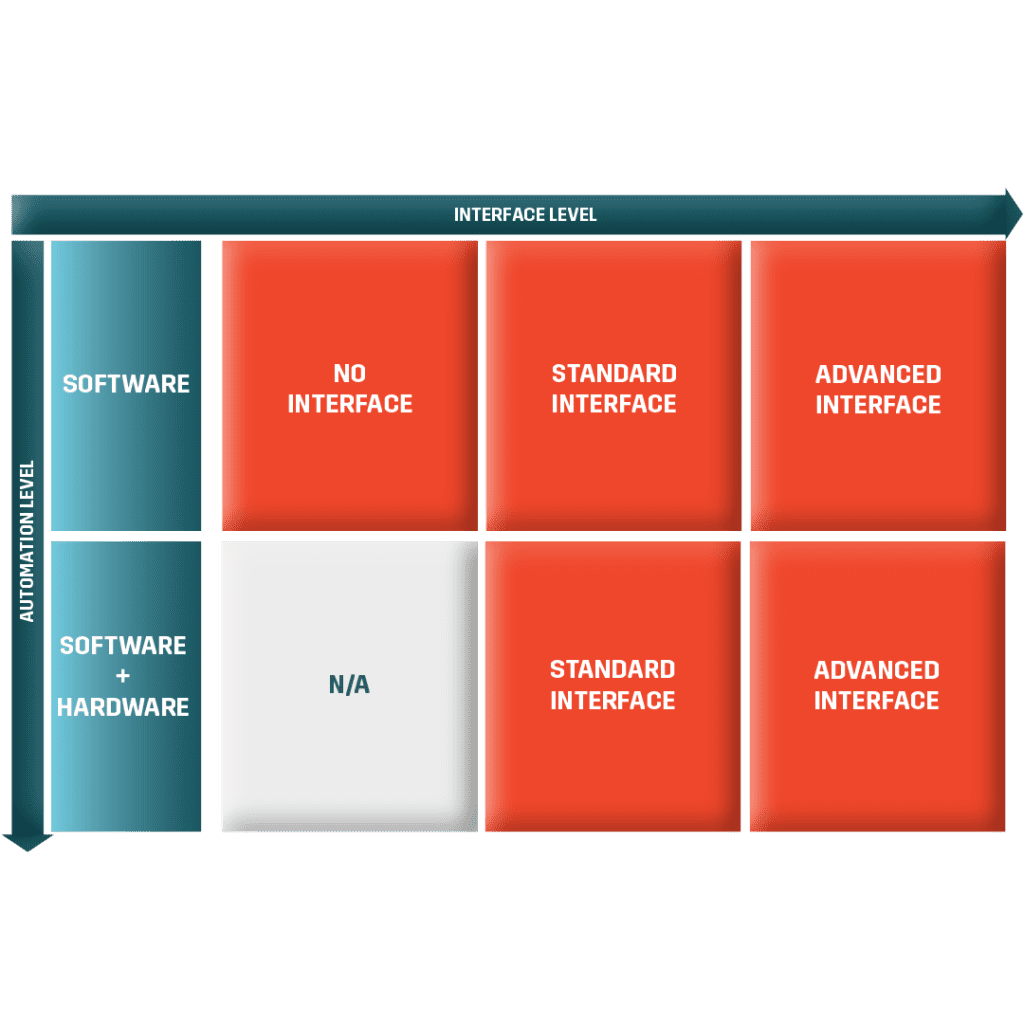

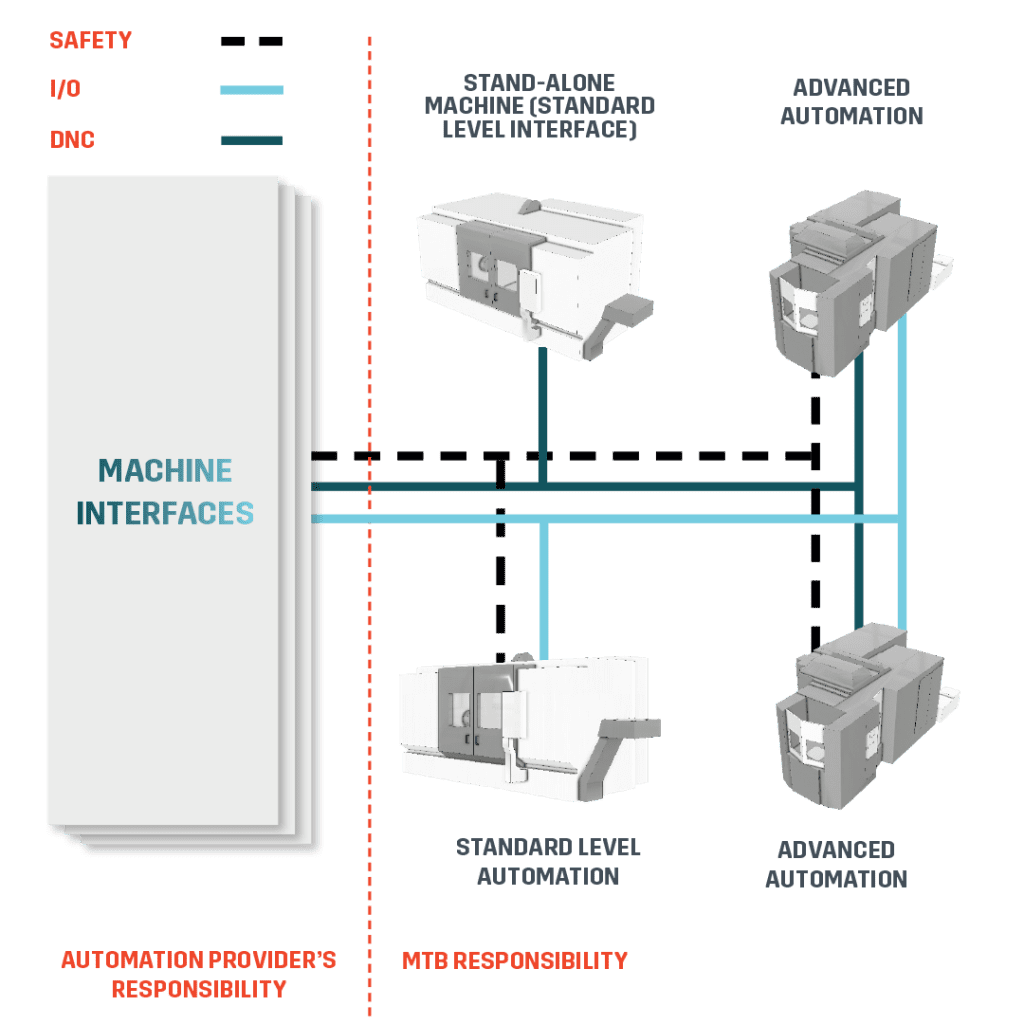

Based on the manufacturer’s need and desired outcome of the project, as well as on the current setup on the shop floor, the level of interfacing is carefully selected and implemented. There are three levels of interfacing, each accumulating into more efficiency and intelligence for the automated production. More information on each is available in the guide:

The first level, no interface, means that there is no machine tool interface or connection, but thanks to the automation software, automated production planning and resource management is added to the production entity.

The second level, standard interface, includes features such as reading the machine status and pallet or part delivery to the machine. This adds the production KPI monitoring and standard automation of the machine tool to the setup, allowing i.e. unmanned shifts.

The third level, advanced interface, adds e.g. NC program transfers from automation system to machine tool and the cutting tool data transfers to and from the machine tools. This level allows full production planning and resource management, now raising the automation level to the maximum.

Interface Development

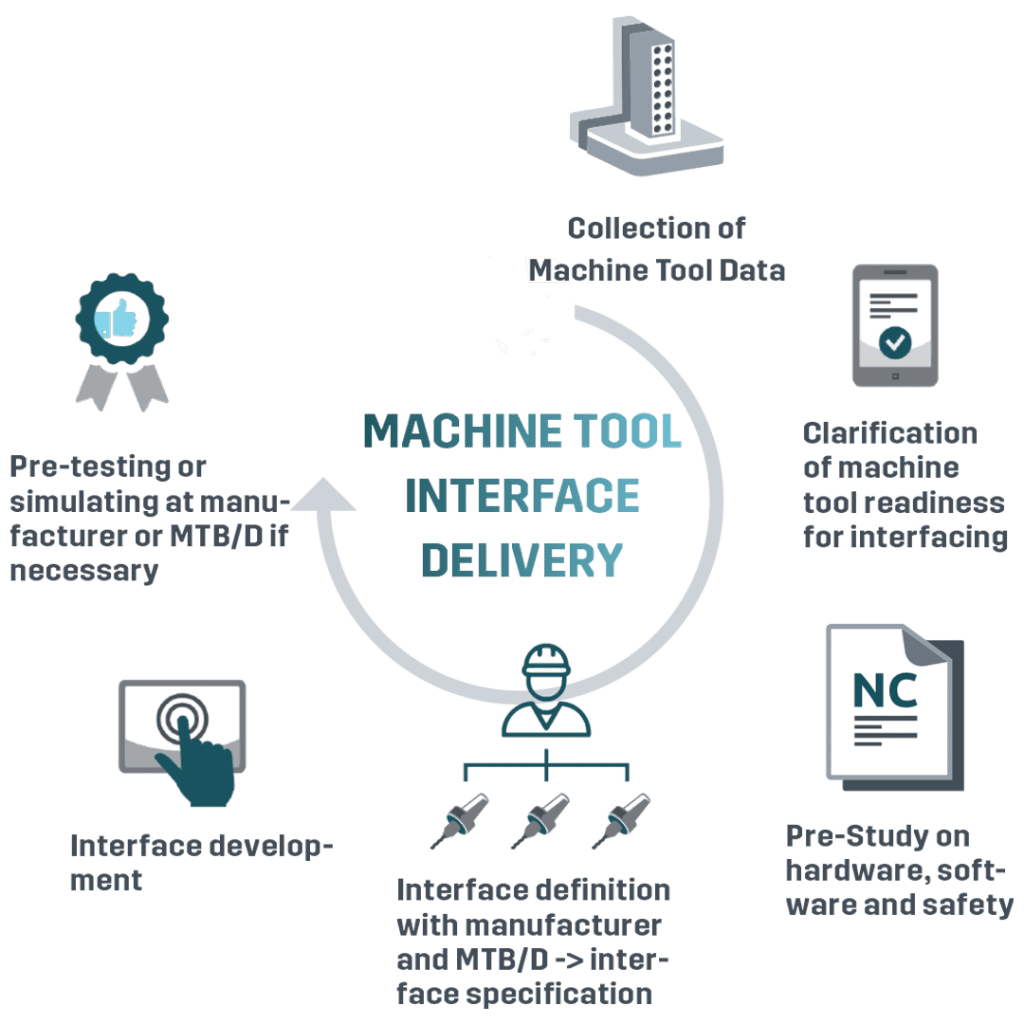

For automating existing machine tools, interface development is crucial. Our interface development process is carried out in six steps: collection of machine tool data; clarification of machine tool readiness for interfacing; pre-study on hardware, software and safety; interface definition with manufacturer, MTB and automation provider; interface development, and pre-testing or simulating at the manufacturer or MTB if necessary.

The collection of machine tool data phase documents the needed information on the machine tool, such as the machine tool brand and model, existing electrical and software connections in the machine tool, and so on. If this is not enough, a pre-study on hardware, software and safety is additionally carried out – these two steps together with the clarification of machine tool readiness for interfacing set the basis of the whole interfacing project.

The interface definition with the manufacturer, MTB and automation provider includes agreeing upon the additional software and hardware interface functions that are possibly missing from the existing setup. After that, the next step is to create an overall specification of the interface together with the manufacturer, automation supplier and the machine tool builder or dealer. The actual interface development is carried out by the automation provider and the machine tool builder, based on the responsibilities defined earlier.

When the development phase is ready, a pre-testing or simulating at the manufacturer or MTB is carried out if needed.

Physical Changes and Safety

When automating, the physical changes to the machine tools vary case by case. Relevant factors are for example, whether the machine is currently integrated to an automation system or if it has an automatic pallet changer (APC). The physical changes on machine tools are always the responsibility of the machine tool builder.

The required safety level can be met either with existing safety features or by adding physical changes or connectivity to the machine tool(s). With standard level interfacing without automation hardware, the machine itself is responsible for the safety features of its own. When introducing pallet or part handling automation, the system will be engineered to correspond to the applicable norms and regulations, such as the standards set by the EU.

Rather talk or mail directly with us?

"*" indicates required fields